Moulds in plaster or resin?

A match-point between quality and convenience

The aesthetic quality achievable with plaster moulds, which is an essential product requirement in some markets, cannot be matched by any other mould material. On the other hand, the production costs are high when plaster moulds are used, on account of the large number of moulds necessary, the necessity for a plaster department, the high wear and the production lost as a result of the downtime for replacing moulds.

In the search for a compromise between production costs and product quality, Bongioanni Stampi based in Fossano, Italy, has acquired wide experience in trialling new materials. The best results could be achieved with the coordination of different technologies. In different applications in various countries in Europe and around the world, it was possible to obtain tiles with a very high quality using combined moulds.

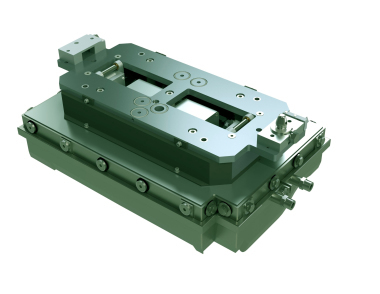

The use of a bottom mould with resin casting and pre-formed membrane (made of a special mixture suitable for electroshock conductivity) combined with a top mould with plaster casting enabled the moulding of a roofing tile with the aesthetic features typical of plaster moulds.

The top surface of the roofing tiles obtained with this technology shows a perfect aesthetic, excellent product definition and a flawless surface structure. The bottom side shows the characteristics of a resin mould associated with a pre-formed membrane, with the advantage of reduced production costs.

The combination of these technologies compared to the traditional solution of plaster moulds allows more flexible and cheaper handling. First of all the investment was reduced for the new model as fewer bottom moulds are needed. The machines stops for the replacement of the bottom moulds are less frequent, so time is saved. The plaster department needs fewer machines, less stock and fewer staff.

To help the customers in project planning and give them the possibility to assure expected results, Bongioanni Stampi in co-operation with Bongioanni Macchine has developed laboratory equipment to run industrial tests in the customer’s factory. With a low investment of the roofing tile manufacturer, it is possible to conduct a production test and evaluate the suitability of the raw material for the use of combined moulds, collecting all necessary data for the investment, based on actual results.

One of the customers switched production to combined plastic-plaster moulds after a test: “After an internal check, it was calculated that for each shift it was necessary to replace between 12 and 15 rubber sheets and membranes for bottom moulds which were damaged, with consequent production stops. At the moment, the tiles pressed with moulds with membrane/plaster are sold at a slightly higher price, but they will soon be placed at the same price as the standard tiles, owing to the following reasons:

Simone Dutto