TRADITION, INNOVATION & SOLID IDEAS

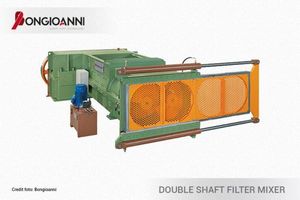

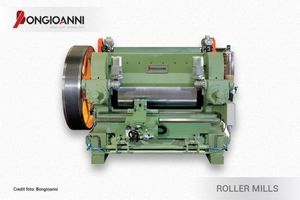

Innovation is the basis of business growth. Bongioanni faces this strong objective of specific investments with the strength of its history which is a symbol of reliability and quality. A new management system, with a cutting-edge technology, starting from offices to the workshop, and with a qualified after sales service, focuses on the needs of each customer. These are the strengths of the new Bongioanni that carries its history forward looking at the future. Today, Bongioanni Macchine continues to be the world leader in the production and marketing of machines and equipment to produce bricks and tiles. The range of machines produced has been completely modernized, adapting it to today's market needs without neglecting the traditional sturdiness, reliability and simplicity of management that has always been a peculiarity of the company. BONGIOANNI MACCHINE is now able to offer you a complete range of machines with very high standards of quality and innovation: clay crushers, excavators, disintegrators, roller mills, double shaft mixers, vertical mixers, extruders, presses for tiles known to be the best in the world.

https://bongioannimacchine.it/heavy_clay_technology/en/10-machines

Furthermore, Bongioanni has worked in improving the interaction between human and machine through a technological solution that gets better the performance of the machine and its safety. This system is called T.E.S. The acronym T.E.S. identifies an integrated system which includes all the elements of the extrusion group that operate in an integrated way to reach our primary targets.

The first target is the reduction of energy consumption, an issue that, in times when the market becomes more and more competitive, allows to reduce production costs significantly. The second target is to ensure a simple and intuitive machine operation, so the site can reduce plant stopping times to the maximum, with obvious benefits in terms of operative costs. The third target is to ensure a safe machine operation. Bongioanni have decided to guarantee the highest levels of safety that can be achieved in accordance with current safety standards. The fourth target concerns the possibility to monitor, also remotely, the condition and the operating parameters of the machine. Bongioanni Macchine has completely redesigned the user interface of the extruder management and control software, based on the principles of simplicity, ergonomics, and energy saving. All operation data are grouped into a single screen from which the operator can monitor and manage the production process. Operating parameters are shown with simple and clear indicators that recall the most used analogue instruments. All indicators show lower and upper limits, control limits and alarm limits for each operation parameter. The software also includes the patented R.A.V. technology, an automatic extruder control technology specially designed for energy consumption reduction. Another interesting feature is the possibility of monitoring, also remotely, extruder conditions and operating parameters, both locally and even from Bongioanni. For instance, the system can be equipped with special cameras for direct monitoring from the control station of all the sensitive areas of the extruder. RAV system can optimize augers shaft rotation speed, adapting it to the operating conditions and reducing it to the minimum necessary.

The T.E.S. philosophy, a system in which all the elements cooperate in an integrated way to offer customers always higher performance.

https://bongioannimacchine.it/heavy_clay_technology/en/machines/28-extruders-type-tecno.html