Clay pavers and facing bricks showing upward trend

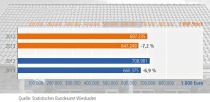

During the first quarter of 2012, facing brick manufacturers produced 119 000 m3 (after 111 000 m3 in 2011 and 71 000 m3 in 2010). The first-quarter production value also increased slightly, from 21.0 million euros in 2011 to 21.4 million euros in 2012. With a production volume of 62 000 m3 during the first quarter of 2012, clay pavers remained stable at their previous year‘s level.

Gardening and landscaping are two areas in which clay pavers are finding more and more buyers and users. All over the world, made-in-Germany clay pavers are in great demand as material for walks and ways thanks to their high quality and durability. Typical examples include plazas, pedestrian zones and seaside promenades in the Baltic states, Russia, the United Arab Emirates, Japan, Shanghai and Spain, as well as Barcelona‘s Olympic Village and the grounds surrounding the GuggenheimMuseum in Bilbao.

Facing bricks have a lot more to offer than just their technical merits. As the “Fritz Höger prize for brick architecture” documents, they also make it possible to implement lots of creative ideas. Back in 2008, an initiative established by leading brick producers called “Bauen mit Backstein” (building with brick) began awarding the prize to deserving projects in the categories single-family/semi-detached homes, multi-storey residential buildings, office and commercial buildings, recreational/sports facilities and public buildings. In addition, two prizes a year are awarded to the best passive house and the best renovation/sustainability project. The competition is worth 10 000 euros in all. For further information on facing bricks and the prize, please go to .