Energy-optimized conveyor belts reduce costs and help the environment

At more than two thirds of the total, the rolling resistance accounts for the greatest share of movement resistance in a conveyor belt system. The rolling resistance is created, in part, by the movement over the idlers. In the contact surface between the conveyor belt and each individual idler, a force arises acting in the opposite direction to the movement of the conveyor belt, resulting in additional energy consumption. In addition to a series of further factors, the rolling resistance depends on the technological properties of the conveyor belt and, more specifically, the material it is made of.

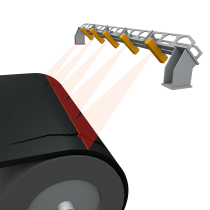

Using complex simulations, ContiTech scientists adjusted the deformation of the conveyor belts over the idlers and derived hypotheses from this on how to provide the ideal rubber compound. On this basis, different compounds were mixed, tested and optimized, and the most promising compounds were turned into conveyor belts in order to try them out and find the ideal solution. And it worked. The latest measurements, taken with special measuring devices on a test rig at the University of Hanover’s Institute for Transport and Automation Technology, showed significant reduction in rolling resistance with the newest energy-optimized conveyor belts from ContiTech. This resulted in an energy-saving potential of about 20%.