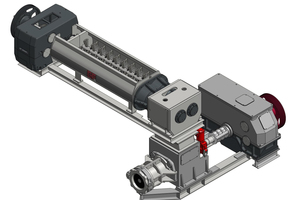

Centra – a new extruder for higher throughput rates

The new Centra model has the capability for fitting larger-diameter worms (flighted screws), from 430 up to 650 mm to suit a wide range of applications. Independent packer shaft drives enable easy access for maintenance, and allow more power to be available from the extruder gearbox for transmission to the main extruder auger shaft.

The extruder has a larger mixing capacity, offers low maintenance and has a more flexible design. It features two separate gearboxes for ease of maintenance access and provides more homogenous mixing capabilities. The extruder itself is also more compact, taking up a footprint of just 6 metres in length, compared with 8.5 metres on similar machines.

Easy access to worms and liners is provided by the hinged extruder barrel, a key part of its low maintenance design. In addition, wear liners are available for the mixer trough in order to enhance the extruder’s durability. Centra’s rigid cast iron gearboxes are fitted with heavy-duty bearings and helical gears throughout.

All Craven Fawcett extruder worm sections undergo in-house treatment to ensure energy minimization, longevity and component quality. After being cast, each worm section undergoes a unique heat treatment process in the company’s own high-temperature ovens in order to ensure an even distribution of chrome throughout the component and enhance its longevity.

The new Centra extruder is suitable for the production of a wide range of products, especially bricks and hollow blocks. Moreover, it can be used for the production of stiff extruded bricks, semi-stiff hollow blocks and various pelletized products, such as iron ore.

Craven Fawcett

www.grouprhodes.co.uk