For straight tracking belts and optimal material flow

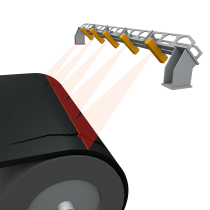

An important step in preventing material losses on conveyor belts is correcting the guidance of the conveyor belt. To achieve this, Flexco Europe GmbH offers a range of different belt positioning systems. Through the use of sensors, these detect misalignment of the belt and correct its directional precision. This also reduces or prevents damage to the edges of the conveyor belts. With these positioning systems, operators not only achieve substantial reductions in terms of material losses, they also reduce their maintenance costs.

Does the belt always migrate towards the same side, or does it move from one side to the other? Is this misaligned travel a constant feature, or just an occasional occurrence? Does the belt get worn in a corrugated manner, and is the belt tension low, moderate or high? Operators ask themselves questions like these in order to select the most appropriate belt positioning system for their needs. Flexco assists them in this process, and offers appropriate solutions for different belt tensions and belt dimensions that are easy to install.

For belts that only migrate to one side, the Flexco “Belt Positioner” offers a simple and adaptable system that is easy to install and maintain. The fixed, angled rollers always hold the belt straight. This system is only installed in the subspace. It is suitable for belts with a maximum tension of 210 N/mm and belt widths of 450-2400 mm.

Flexco recommends the PT Smart series whenever belts are exposed to moderate tensions of no more than max. 280 N/mm. Sensor rollers detect whenever the belt starts to move out of alignment. The unique pivot-and-tilt movement then returns the belt to its correct alignment position. PT Smart can be installed in standard size for belt widths of 400-1800 mm and up to a thickness of 25 mm. Flexco also has such positioning systems in its portfolio specifically for use in underground mining applications. These are made of materials and components that have been specially adapted to withstand the unusual temperature and application conditions that exist in these harsh environments.

Where tensions are very high, i.e. up to 525 N/mm and where belts are concave, the PT Max range is recommended. This also uses sensor rollers to detect whether the belt is starting to migrate. The belt is then guided back into its correct position. Depending on the application, the operator can install these systems either above or below the belt. They can be used in humid as well as in dry environments. The standard sizes of this series are suitable for belt widths of 650-1400 mm. The return side version is suitable for thicknesses of up to 25 mm, while the top-mounted version is suitable for thicknesses of up to 19 mm.

Operators of heavy belts that are under great tension of up to max. 1060 N/mm rely on HD PT Max. This series works like its PT Smart and Max counterparts. Depending on the application, it can also be mounted above or below the belt. It is designed for belt thicknesses of 1200 mm and up.

www.flexco.com