Keller Division supplies grinding machine to Schumacher Brickworks, Switzerland

The family-owned Schumacher Brickworks, Körb-lingen, has been producing a wide selection of high-quality bricks for six generations. The long-established company can look back on over 150 years of history.

With the installation of a modern unloading plant, using robot technology, and an integrated 900air+ grinding machine from Novoceric in Mellrichstadt, the Schumacher family continues its commitment to upgrading and automating the brick production processes at its Gisikon site. With the commissioning of the modern robot unloading plant, the process of brickmaking, starting at the press and continuing with drying, setting and unloading, was modernized and automated within a very short period of time. This is now the third plant Schumacher has implemented together with Novoceric, reflecting excellent and close relationship between customer and supplier.

Very often new technology goes hand in hand with new products, and Schumacher immediately came up with three newly developed bricks for highly effective heat-insulating brickwork. The top product in this series is the high heat-insulating Monobrick ZSK which offers optimum values for thermal insulation. These bricks are bonded together with thin-layer mortar (2 mm). For bonding with thin-layer mortar, the fired bricks are ground fully automatically with the 900air+ new grinding machine made by Novoceric in a continuous process with an accuracy of

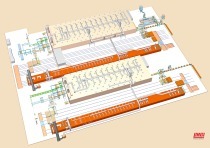

± 0.2 mm. This highly flexible grinding machine is designed for the future as both the grinding width (between 199 and 600 mm) and the grinding height (between 40 and 600 mm) can be freely adjusted. The maximum grinding speed is 20 m/min. The grinding disc diameter is 900 mm.

The machine consists of two grinding stations, each having two motor-driven grinding wheels. During the grinding operation, the patented air distribution system ensures a continuous flow of air that removes the accumulated dust from the grinding wheel and at the same time ensures necessary cooling during the grinding process. A proven transport system working with toothed belts routes the bricks past the grinding stations. Sophisticated drive technology with frequency-controlled drives and servo motors ensures that the transport system works with the necessary high precision while minimizing the electric energy needed in this process. The reliable plunger system of the top pressure bar is capable of compensating height tolerances of up to 15 mm without any problem. The pressure bar is separated into sections and can always keep the passing bricks in the correct position by applying different pressure forces, if necessary, in its individual sections. A patented laser measuring method always guarantees the required grinding precision. This laser measurement device succeeds in not only managing the grinding precision of the brick but it also compensates for wear of the grinding wheel itself.

The complete grinding machine is housed in a sophisticated soundproof enclosure which perfectly meets the high requirements set for noise protection in modern industrial plants. The complete plant can be operated from a central operating panel equipped with a touch screen.

The grinding dust from the grinding process is extracted through a pipe system which is part of the Hellmich de-dusting plant and is pneumatically conveyed to a storage silo in the material feed area of the box feeder. The grinding dust is then gradually dosed into the production process. This procedure also completes the circuit flow for the accumulated grinding dust.

A robot moves the fired bricks from the kiln car to the unloading plant with the grinding machine. The unloading plant can handle all product sizes (approx. 100 pieces), either ground or unground.

The dispatch packs are formed exclusively with a fully automatic robot. Here, at the request of the customer, highly flexible equipment was installed to allow the forming of dispatch packs on Swiss pallets or Euro pallets. A stretch hood machine supplied by Lachenmeier covers the dispatch packs with weather-proof film hood and secures them for transport. Contrary to a shrink-wrapping process with combustion gas, this technology requires no additional heating energy. Of course, the red flame with the “S“ for Schumacher remains clearly visible on the film hood. The completed dispatch pack then waits on a chain conveyor to be picked up by a fork-lift truck.

One plant operator manages the complete de-hacking plant from a central control panel. All configuration data for the individual plant areas can be viewed and modified, if necessary, on this panel. Pre-selection of the kiln cars according to the different product settings is also made here.

Through continuous investment, the Schumacher brickworks have always succeeded in updating their plant to the latest state-of-the-art technology, and with highly motivated staff the company is in a position to make high-quality products in line with market trends.