Kick-off: Research project on hydrogen as an alternative fuel for tunnel kilns

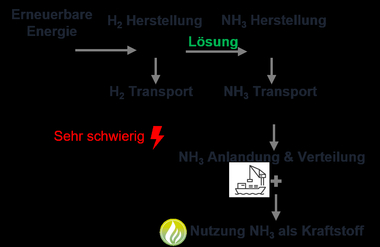

Over the next few years, a consortium of companies and research institutes will be working on the development of a new tunnel kiln concept that operates with hydrogen as fuel. The hydrogen project has been launched under the auspices of the Federal German government’s hydrogen strategy and under the pressure of the energy transition with an initiative of Kärlicher Schamottewerke (KTS) in cooperation with the Glass-Ceramics Research Institute (FGK). The first application phase has been concluded, and the submitted sketch is currently being scrutinized by the German Aerospace Centre (DLR) in the scope of the KlimPro Industrie research programme launched by Germany’s Federal Ministry of Education and Research (BMBF).

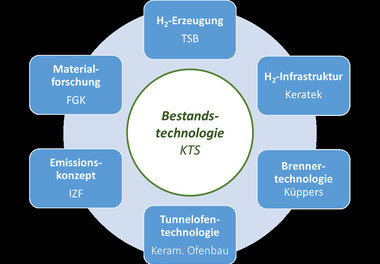

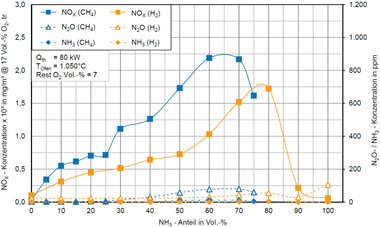

The project consortium aims to work out an integrated concept for a hydrogen-driven tunnel kiln. Work on the integrated concept is structured in three key areas, a research institute being assigned to each area to address the relevant scientific issues. The selection of the technology and the costing for hydrogen generation, efficiency assessment, lifecycle analyses are the responsibility of the Transferinitiative Bingen (TSB). The tunnel kiln technology itself is being developed by the industry, studies of the emissions have been identified as a key aspect and have been undertaken by the Brick and Tile Research Institute Essen (IZF). The FGK is investigating changes in sintering behaviour as a function of change in atmosphere conditions. The companies engaged in the development of the tunnel kiln technology are Keramischer Ofenbau for the design of the tunnel kiln, Küppers Solutions for development of the burners and the sensors, as well as Keratek for planning of the infrastructure. The Energieversorgung Mittelrhein (EVM) and Weissenthurm’s local authority are associated partners.

An assessment of the sketch is expected by the research project sponsors in the second quarter of 2021 at the earliest. The application will only follow then. The project may then start in the fourth quarter of 2021, although the situation is currently unpredictable owing to the pandemic.