Modern raw materials for the clay brick and tile industryPart 1: Filter cake from the Ottenhöfen rhyolite quarry

It can take up to 20 years to obtain a permit for new quarry excavations. Raw materials are not just becoming scarce for geological reasons, but artificially scarce for political reasons, too. Moreover, the German brick and tile industry wants to become climate-neutral. A huge challenge. New approaches and lucrative solutions are needed.

1. Geological background and site

Rhyolites are leucocratic, thus light-coloured siliceous volcanic rocks with a crystalline and partly glassy matrix. They consist predominantly of quartz and alkali feldspar. Other feldspars and micas like biotite can be present as accessory constituents. Rhyolites used to be called porphyrys or quartz porphyrys – names that are still found widely in the literature and daily life today.

At Ottenhöfen, rocks of different rhyolite varieties have been quarried since 1926 and processed to high-grade raw materials for road and rail construction. As secondary raw materials, in the course of rock washing and washing water recycling, clay mineral filter cake is produced. The quarry with the fabulous name “Edelfrauengrab” (“noblewoman’s grave”) is operated by Wilhelm Bohnert GmbH & Co. KG and is located near the A5 motorway. Karlsruhe Harbour is currently the most convenient option for ship loading.

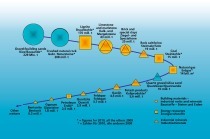

Geologically the quarry is located on the western edge of the Northern Black Forest and therefore in the Moldanubian Zone of the Variscan orogeny. In the time of the Lower Permian/Rotliegend, around 298.9 to around 259.2 million years ago, as in the whole of Central Europe, a fundamental change took place from compressive to expansive tectonics. As a result of thermal subsidence, numerous sedimentary basins and rift valley systems were formed (»2). In tectonic weakness zones, rising mantle magmas caused continental volcanic activity with predominantly andesitic and rhyolitic lavas. The rhyolite from the Edelfrauengrab quarry is a 4-km long and 750-m-wide fissure filling within the Palaeozoic bedrock. On account of the great depth, the land used by the quarry is limited. The current mining depth is around 230 m.

The region that is Germany today was located at the time of the Rotliegend somewhat north of the Equator, comparable with the position of North Africa today. As a result of the levelling of the Variscan Mountains, strong erosion and coarse-grained sedimentation predominated. As a result of the gradual northward drift of Pangaea, the originally tropical and humid climate changed to a dry and hot desert climate with typical iron-rich red beds.

2. Mineralogical and chemical composition of the filter cake

The mineralogical composition of the primary rhyolite is reflected, as expected, only relictically in the mineralogical composition of the deslimed fines. Crucial for the mineralogical transformations are primarily type and intensity of the weathering processes that have acted on the primary raw material basis over millions of years. Besides this, secondary fissure and pipe filling have a crucial influence on the mineralogy of the fines.

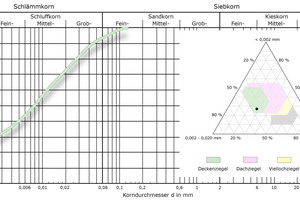

The Ottenhöfen filter cake has a grain structure dominated by silt with an average finest grain content of d < 2 µm = 27 mass%. The screen oversize d > 63 µm averages 7 mass%. Even without any processing, the particle size distribution of the filter cake corresponds to that of a narrowly graded roofing tile body (»3).

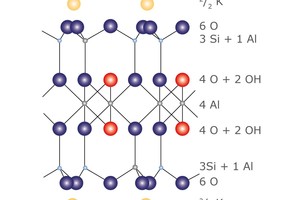

Mineralogically, the filter cake is characterized by a significant content of phyllosilicates, especial potassium-rich three-layer silicates of the mica group. With the strong bond of the potassium ions to the negatively charged basal planes of the tetrahedron layers, the expansion of the crystal lattice with innercrystalline swelling is largely inhibited (»4). In terms of quantity, illites with smooth transitions to larger muscovitic micas are the dominant phases. These are followed by innercrystalline swelling illite-smectite alternating layers and small percentages of kaolinite. In the series of the tectosilicates, quartz is present before potash feldspar and albite. Goethite is detected as an accessory mineral phase. Problematic mineral phases such as carbonates, sulphides or sulphates cannot be detected in the filter cake (»Table 1).

In chemical terms, silicon and aluminium clearly dominate before all other elements. As a flux, potassium is the key influence on the properties. The high potassium content results mineralogically not only from the mica minerals, but also from the potash feldspars. The total organic carbon is low and averages around 0.08 mass%. In combination with the simultaneous absence of carbonates, this results in only a minimal CO2 emission of 0.29 mass% (»Table 2).

3. Ceramics-related characteristics of the filter cake

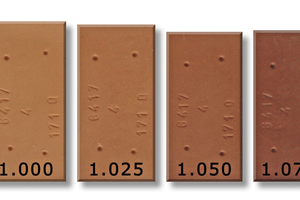

The filter cake is free of any problematic coarse particles and characterized by a stiff plastic to semi-solid consistency. As part of the preparation, the filter cake does not have to be comminuted in an energy-intensive process, but only mixed homogeneously with the other body components. The filter cake is ideal for processing in conventional brick plant preparation equipment. The filter cake exhibits medium-plastic properties and can be moulded well. On account of the limited content of expansive clay minerals, no particular sensitivity can be expected during drying and preheating. In the firing process, the filter cake is very reactive and starts sintering early on. This is reflected in the high firing shrinkage and the low water absorption of the fired body (»Table 3).

Already at 1 000 °C, clinker brick properties are obtained. The material shows no swelling tendency but does react with high sensitivity to temperature differences in the kiln (»5). An increased sensitivity to preheating and cooling cracks cannot be observed. As a low-carbon additive, the filter cake can be used universally in batch percentages between 10 and 30 mass% in the clay brick and tile industry. The preferred application is currently in the production of floor tiles and roofing tiles. In the case of backing bricks with high thermal insulation, an increase in the compressive strength can be expected given sufficient addition of the material.

4. Volume availability and final remarks

Following the ejection from the chamber filter press, the filter cake is stored intermediately in large-size clay storage facilities. This ensures availability all year round. It also avoids uncontrolled wetting by heavy precipitation. The annual quantity available long-term is currently only around 10 000 t. The data specified are guide values and can be subject to the usual natural fluctuation. No liability or guarantee is accepted that the information provided is up to date, correct and complete. All information is non-binding.

![»2 Palaeogeographic map of Central Europe at the time of the Rotliegend [3]](https://www.zi-online.info/imgs/1/6/5/1/4/7/7/tok_c9b7ca99bb9ed49bac62f3ff6563415e/w300_h200_x600_y279_Bild_2-1955bf4abae27f45.jpeg)