Optimizing the operation of industrial furnaces economically

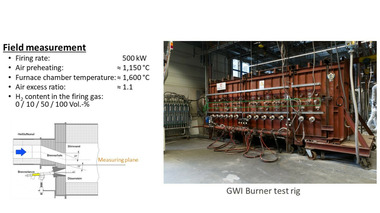

A realistic service life calculation of components can help making the operation of industrial furnaces even more economical in the future. In a joint research project the Oel-Waerme-Institut (OWI), the Institut für Industrieofenbau und Wärmetechnik (IOB) of the RWTH Aachen and the Institut für Werkstoffkunde (IfW) of the Technische Universität Darmstadt have gained new important insights into this and implemented them in the development of a method for calculating service lifes. Manufacturers of industrial furnaces may use the research results for a more reliable design of furnace components....