Upcycling firing – bricks for an optimum eco balance

Using the new raw material-neutral and resource-efficient upcycling firing process, Hagemeister responds to the growing requirements in the construction industry and makes an important environmental contribution, according to a statement of the company.

The particular feature of the so-called upcycling firing is the consequent and exclusive use of raw materials which were separated in previous production processes. In this way, for example, unfired raw material is used that is produced in the manufacturing and conveying systems when changing between two grades. In addition, ceramic raw material is used that can be extracted from the filter of the in-house water treatment. Even fired brick waste is finely ground and used as component in the upcycling firing process. As a result of this measure, it consists of 100 % secondary material. No raw material freshly delivered from the clay quarry is required.

Recipe is determined by the secondary material

Hagemeister breaks new ground with this procedure: So far, a clinker grade was produced strictly according to the recipe. Now the exact opposite procedure is used for upcycling firing. The recipe is essentially determined by the secondary material available – the firing result is unique and depends on the composition of the recycled material. „However, the visual appearance of firing is not at all left to chance,“ explains product manager Johannes Beusker. „Together with architects, investors and building contractors, we can coordinate relevant parameters such as shape, surface structure and method of firing in advance. In this way, also upcycling firing can respond to the design requests of the construction partners.“

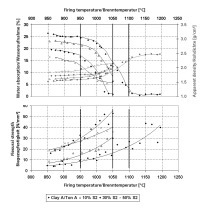

Prior to the upcycling firing process, a sample of the resource-conserving raw material available is analysed in the internal laboratory and fired for testing purposes. This procedure guarantees the Hagemeister quality in this particular production process too – so that the products manufactured in this way fulfil all technical requirements on the high-quality clinkers. Moreover, the result of the test firing is a good indication for the later clay colour on the basis of which the final look of the product is designed in coordination with the customer.

The offer of upcycling firing is addressed to architects who think sustainably as well as building contractors who are planning a larger project and are possibly interested in having the building certified under aspects of sustainability.