All types of businesses

utilize different management systems to check and control their procedures. Weekly production and target schedules to determine procedures or other aims to achieve further business objectives could be seen as an example of this. Examples of standardized management systems that have been implemented successfully by a number of companies are:

› �Quality Management in accordance with EN ISO 9000 ff.

› �Environmental Management in accordance with EN ISO 14001 ff.

Apart from the desire to improve quality and to reduce ecological damage, these guidelines have also had a considerable side-effect in marketing for many companies and organizations.

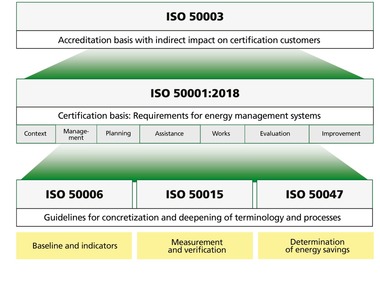

The standard for the Energy Management EN 16001 was the basis for Environmental Management in the same way as the structure of the ISO 14001 had been built on ISO 9001. DIN EN ISO 50001 was, in great part, taken from DIN EN 16001 for internationalization purposes. It has had full validity since July 2011 and will replace the standard DIN EN 16001 in 2012 with a transitional phase to the end of April 2013.

Reasons for introducing an Energy Management System

› �Reduction of energy consumption leading to reduced energy costs

› �Possible profits owing to statutory compensation schemes

› �Sustainable management resulting in improvements in environmental protection

› �Use of Energy Management as a marketing tool

Introducing an Energy Management System in a manufacturing company does not only mean additional costs but offers multiple opportunities by implementing best practice methods of continuous improvement processes. Energy cost savings should not be a one-off experience. The aim is a continuous reduction in energy consumption resulting in continuous energy cost reductions. Continuous awareness for employees to recognize, evaluate and minimize or even to remove inefficient energy consumption mechanisms are encouraged.

Statutory compensation schemes, which, in Germany, will only be available to companies and organizations that have introduced Energy Management in accordance with ISO 50001 after 2013, are further substantial incentives.

The plant manufacturer Lingl, a specialist in all areas of the value creation chain in the production of ceramic building materials, will be able to give competent support to plant operators in the introduction and implementation of an Energy Management System. Our know-how covers three aspects:

› �Engineering

› �Energy monitoring software

› �Hardware installation

1 Engineering

When introducing an Energy Management System, the energy consultant, who supports the company that, in due course, will receive relevant certification, will receive a complete overview of the energy flow in the manufacturing plant. To do this the factory or production line needs to be broken down into “measuring rooms”. A measuring room is defined as a production unit with input and output parameters as well as other factors that influence energy consumption (i.e. ambient temperature).

1.1. Example Tunnel Kiln

Input parameters

› �Electricity

› �Gas

› �Compressed air

› �Additional air

› �Brick tonnage with x input humidity

Output Parameter

› �Exhaust air quantity

› �Hot air quantity

› �Brick tonnage with y exit temperature

› �Under car temperature

Factors

› �Calorific value of the fuel

› �Ambient temperature

Energy factors are therefore indispensable to be able to make suitable consumption comparisons, for instance between different facilities but also between seasons.

In general, no additional equipment, neither in the form of measuring equipment nor monitoring software, is necessary at the time of certification (first audit). At this point in time, it is, however, of great importance to clearly present the energy and production flow in the measuring rooms. It is advantageous if proposals that are to be presented in future annual audits are already prepared for this first audit, such as:

› �Installation of an Energy Monitoring System

› �Installation of certain measuring equipment during the first year after certification (for the first monitoring audit)

› �Measures for the reduction in energy consumption in the first year after certification

› �Installation of further measuring equipment in the second year after certification (for the second monitoring audit)

› �Measures for the reduction in energy consumption in the second year after certification

Experience gained over many years by Lingl in the installation and commissioning of operating data recording systems and also by giving support during audits, the manufacturer can be assured of a competent partner for their energy consultant.

2 Energy Monitoring Software (EMS)

An Energy Management System is based on recorded data and knowledge gained to optimize production processes and to plan new installations to reduce energy consumption.

It is imperative that consumption and corresponding production data is collated at the latest by the first monitoring audit after successful certification.

There are a number of software tools available for energy monitoring in today’s market. However, after closer inspection it became apparent that these readily available programs are Expert systems and, unfortunately, do not have all necessary functions. A key factor of “live” energy monitoring software is the ability to expand recording and evaluation of any particular level of detail for energy management, which can only be achieved with suitable basic knowledge in the PLC technology and parameter functionality. The software needs to have sufficient parameterization flexibility to cover the adage “Who knows today what factors will be relevant tomorrow” (»1)

Simatic S7-modules read and format the digital and analogue values. A database concentrator reads this via an OPC-server connection and archives the results in a SQL-server database. Lingl includes an extensive S7-function block pool for necessary expansions.

The following control modules are necessary:

› �Read and convert analogue values

› �Counter modules

› �Conversion and standardization modules

› �…

New intelligent smart counters or also multi-function units, i.e. intelligent counting equipment, can be read via field bus systems (CAN-Bus, Profibus or Profinet/Ethernet).

As only a small number of manufacturing units are equipped with the latest control components, older control systems (i.e. Simatic S5) are also evaluated. At the point of service delivery a decision will be made whether it is more sensible to collate the data from various control generations or whether it would be easier to install intelligent terminals and to link these to a Simatic S7.

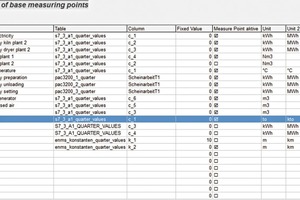

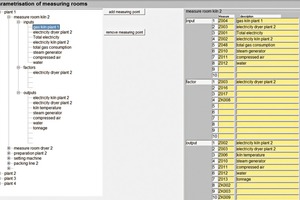

The measuring positions can be assigned to one or several measuring rooms once they have been defined in the EMS (»2).

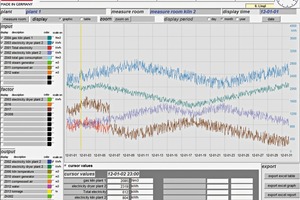

From this point onwards, the measuring values can be displayed in full graphic or tabular form on the display screen (»3).

The following display functions are available:

› �Select measuring room to be displayed

› �Select measuring positions in measuring room

› �Graphic or tabular measured value display

› �Select display period by day, month or year

› �Free date entry to display earlier measuring values

› �Ruler/spacer function

› �Zoom function

› �Export function to Excel and PDF reports

Energy management also requires routine checking of the functional efficiency of the installed measuring equipment. The software supports this in two ways: An upper and lower limit value alarm can be preset for each measuring position. Carrying out calculations at measuring positions (i.e. total power consumption minus power consumption of individual units) enables the localization of increasing transformer losses or measuring position drift.

The server software can be run on a standard PC without any special CPU and storage requirements. All data is stored locally on the server PC. The necessary data safety for complete energy management can be guaranteed with the automatic local database safety or on a separate server.

The philosophy of the EN 50001 is that all employees of the company are aware of energy management and that everyone contributes in their own way towards this as well as taking this forward. Software design has taken this into consideration enabling operation for several clients simultaneously. Password-dependent user authorization enables user-friendly software operations.

3 Hardware installation

In addition to the evaluations and results of the energy management based on the EMS, annual technological improvements should also be included and reported during the audits. Based on its extensive experience in plant engineering and pro-cess technology, Lingl can provide advice and assistance in this area. Lingl can work out reliable concepts and projects to save energy by taking a number of measures, i.e.:

› �Test for leakages (air, gas)

› �Analysis of the raw materials, the drying and firing processes

› �Replacement of compressors

› �Installation of frequency regulators, energy-efficient electric motors, additional electricity, gas and water meters and air quantity meters

The complete spectrum from relatively simple servicing activities to complex measures is possible. The expansion of the EMS will need to be carried out to be able to document annual improvements.

4 Summary

The Energy Monitoring Software EMS is a significant component of the Energy Management System. It supports the company by recording the necessary energy-relevant data and, with possible evaluations, assists in decision-making processes for future investments. The continuous internal improvement process to minimize energy consumption requires user-friendly and expandable software. Apart from this software, Lingl also offers support by working out concepts and projects to save energy. This provides an optimum basis for the introduction of active energy management.

The Energy Monitoring System is a “green tec by Lingl” product. Lingl has chosen this concept to summarize all innovations for efficient production technology and optimized processes for the heavy ceramic value creation chain. The aim of these developments is to substantially reduce environmental impact and to reduce operating costs long-term. Other tried and tested solutions and products under the label “green tec by Lingl” will be published in the coming months.