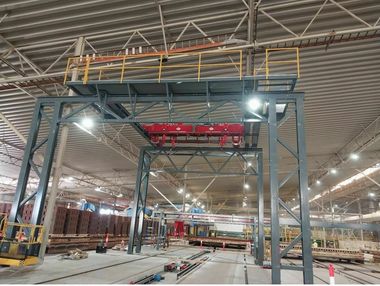

Ceric commissions one of the largest Australian plants for BGC in South Guildford (Australia)

In 2007 BGC and Ceric Australia signed a contract for the erection of one of the largest brick plants in Australia comprising two production lines equipped by different suppliers. The Ceric offer comprised its services and substantial experience in product and kiln car handling, as well as the supply of two Anjou dryers, three Casing kilns and the related computerized supervision systems. The facing brick production line supplies a tunnel kiln which is regulated and controlled by Ceric supervision equipment. The firing cycle of the products in Casing kiln 2 is 44 hours. The remaining equipment for this production line comes from various foreign plants which had been bought directly by BGC.

The production line for masonry bricks feeds two 2 Anjou dryers with a Tecauma handling system. In each case the firing cycle in the Casing kilns 1 and 3 amounts to 22 hours.

The production of masonry bricks and facing bricks started on the 11th November 2008. The second kiln went into operation on the 24th December 2008 and the third and last one on the 10th October 2009.

Due to these investments, BGC will be able to market 110 million standard bricks per year once the mass production with the three identical kilns installed has reached capacity. One standard perforated brick weighs approximately 2.8 kg, which corresponds to a daily production of 850 tonnes on average.

The high capacity of this new production centre puts the BGC in the position to cover the entire western Australian market and then take over the market leadership in terms of the production of clay building materials. It is planned that BGC will use their own building materials for the construction and expansion of the residential parks they are developing.