IZF is H2-Ready - test firing plant for the brick industry with hydrogen

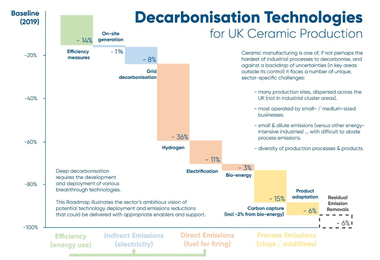

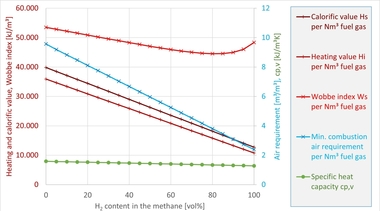

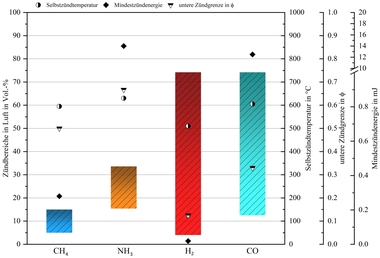

Hydrogen is seen as a guarantor for defossilisation (decarbonisation) also in the brick industry. In addition to the questions of supply security and hydrogen handling, the focus is primarily on product qualities and the opening of new innovative process and product developments. As an energy-intensive process, brick firing is decisive for product qualities. In addition to energy-related issues, the effects of changing kiln atmospheres and adjustments of the firing curves to other firing gas qualities are essential topics for the decarbonisation of the brick industry.

The existing gas-fired test kiln at the IZF was converted and expanded to include the supply of up to 100 percent pure hydrogen. The supply of the required gas mixtures is ensured via cylinder bundles. This enables the IZF to investigate, evaluate and optimise the pressing questions regarding the differences and expected influences on the products of the brick industry, such as vertically perforated bricks, roof tiles and clinker bricks.

In practical firing tests in the IZF‘s pilot plant, it can thus be evaluated to what extent the firing process with rate-wise addition of hydrogen to the firing chamber atmosphere is comparable with the previously common, pure natural gas firing and optimisations of the firing process and the material mixtures can be made. The kiln can be operated in the temperature range up to 1,200°C. Both the course of the temperature in the product and the gas temperatures as well as the occurring emissions are recorded and subsequently analysed and evaluated. In conjunction with the IZF‘s expertise in ceramics technology, questions concerning the product „brick“, with regard to material mixtures, maximum firing temperatures and strength, are thus also extended to the use of hydrogen.