The United Kingdom’s brick and tile industry is testing feasibility of hydrogen for firing

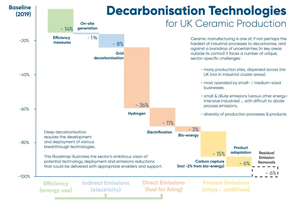

At the moment, the British brick industry is busy exploring the use of hydrogen for decarbonising brick production, as is the British ceramics industry as a whole. Their trade association, Ceramics UK, formerly British Ceramic Confederation (BCC), representing 90 percent of the British ceramics producers, has highlighted the relevancy of hydrogen for reaching climate neutral production conditions in January 2024 with the publication of the Decarbonising UK Ceramic Manufacturing Roadmap.

Ceramics UK is at the moment pursuing research into the use of hydrogen, as are several brick producers as well.

Hydrogen’s projected role in decarbonizing UK’s brick industry in the Roadmap

The Ceramics UK’s Roadmap illustrates the UK ceramic sector’s maximum potential emissions reductions contingent on a supportive decarbonisation landscape. Regarding direct emissions from fuel for firing, hydrogen is projected as the main contributor to CO2 reduction. While electrification to a larger and bio-energy to a smaller extent are thought to contribute around 40 percent, hydrogen is projected to “account for ~60 percent of fuel-switching emissions reductions“. Regarding total Scope 1/2 emissions reductions, hydrogen is still planned to amount to 36 percent. In short, hydrogen will be indispensible for the UK ceramics and brick sector. Therefore, the roadmap concludes: “The distribution and use of hydrogen by the industry (at its dispersed sites) is crucial to the future of UK ceramic manufacturing. As a hard-to-abate application, ceramics should be a ‘priority use’ application.“

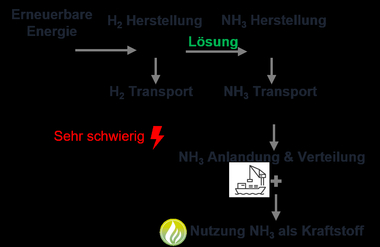

Hydrogen is seen as the principial future alternative for natural gas as the predominant fuel currently used. To achieve this, development of the hydrogen supply chain and market, including infrastructure and supply distribution, is seen as a crucial prerequisite to its commercial adoption by companies. This network is to focus around industrial clusters and to expand to dispersed areas as well. Lastly, self-production of green hydrogen is named as a possible source, albeit as a more far-fetched variant.

While still in the early stages, a comprehensive hydrogen network with a focus on transportation, storage, and potential blending with existing gas networks is being developed in the UK. According to the Energy Networks Association (ENA), especially for decentralized industries, like the brick industry, converting existing gas networks would be the most cost effective way. Key issues like CO2 neutral supply and economically viable pricing are being discussed. According to ENA, early supply should be focussed on blue hydrogen and using Carbon Capture and Storage (CCS). The price of hydrogen should be lower than the natural gas plus CO2 price to manage the risk of early adoption.

Precursing this, viability of firing with hydrogen is being assessed (as an alternative for natural gas-fired kilns) with trials across the UK ceramic sector taking place. A number of small scale projects / activities (by both consortium groups and individual companies) have been underway to-date, ranging from 20 percent hydrogen : 80 percent natural gas blends, through to 100 percent hydrogen-only supplies.

Ceramics UK’s hydrogen project reaches milestone – custom-built pilot kiln successfully operating on 100 percent hydrogen

In an article on their website dated 24 January 2025, Ceramics UK announced that a key milestone in their hydrogen project‚ ‘Demonstrating Hydrogen in the Ceramics Sector’ has been reached. After successfully commissioning the custom-built pilot kiln, it is now operating on 100 percent hydrogen. Trials firing member-produced ceramic products with hydrogen have officially commenced.

“This is a pivotal moment in our journey towards a sustainable future of the UK ceramics industry,“ Ceramics UK CEO Robert Flello adds. “The successful operation of the pilot kiln on 100 percent hydrogen and the initiation of member product trials represent a significant milestone of the project and a crucial step towards a lower-carbon future of the sector.“

“Our groundbreaking work during Phase 1 of the project in 2022, believed to be a world first, demonstrated the technical feasibility of firing various ceramic products with 100 percent hydrogen – a key decarbonisation option of the sector – without impacting product quality,” said Dr. Andrew McDermott, Deputy Chief Executive of Ceramics UK and Project Lead. “Commissioning of the new pilot kiln to operate on 100 percent hydrogen marks another major milestone in the project. The kiln is custom-built and highly-instrumented to allow us to study in detail the hydrogen firing of ceramics under a range of conditions. Later this year we intend to complement this work, by also demonstrating the ability to retrofit an existing methane-fuelled production kiln to operate on 100 percent hydrogen.”

In 2023, around 6 million pounds funding for the project was awarded by the Department for Energy Security & Net Zero through the Industrial Fuel Switching Phase 2 Competition, as part of the £1bn Net Zero Innovation Portfolio (NZIP), which supports innovation in the development of pre-commercial fuel switch technologies to help industry transition to lower-carbon fuels.

Forterra running successful trials with 5 to 20 percent hydrogen blend

According to a press release on the webpage of Air Products, a world-leading industrial gases company, the company has recently worked with Forterra, a leading UK manufacturer of essential clay and concrete building products, on a successful trial to reduce carbon emissions during its production process by introducing blend-levels of hydrogen to power the company’s brick product kilns.

At its production site Red Bank in Measham, England, Forterra trialed up to a 20 percent hydrogen blend with 80 percent natural gas as an alternative to pure natural gas in its kilns.

“Cutting our carbon emissions is central to our mission, but we need to make sure we’re not compromising on the quality of the products we’re producing,” said David Manley, Forterra’s Head of Sustainability. “When it comes to considering how to cut our emissions, we looked at several options including electrification and biomass. Both of these will have a supporting role in our long-term strategy, but it became obvious quite quickly that hydrogen is the most effective option for reaching our long-term decarbonization targets.”

Overseeing trials using a 100 percent natural gas kiln as a control variable, Forterra used hydrogen at rates between five and 20 percent, increasing the volume of hydrogen use as the pilot project progressed. Adding hydrogen in a staged manner allowed them to pinpoint to what extent hydrogen could be introduced and used effectively in the production process. At the highest blend of a 20 percent hydrogen mix, there was no impact on the color, consistency or quality of the bricks.

Excited about the trial outcome, Manley announced further trials: “As a result we’re now exploring how we can do a similar trial on a slightly smaller kiln but with hydrogen blends of up to 100 percent, as well as how we would fill out our larger kilns in the future.”

Testing details

According to Forterra, instead of constructing trial-specific kilns, existing machinery was used to see if its current legacy kiln equipment could adapt to the new hydrogen blend. David Fox, Capital Engineering Manager at Forterra, is glad to report that the 20 percent hydrogen blend is fully compatible with existing kiln equipment. Fox finds that encouraging: “Our kiln equipment tends to have a lifespan between 25 and 40 years: replacing it would incur significant carbon costs.”

To ensure consistency in the testing process, Forterra tested its Measham buff bricks and Desford red bricks, with special attention given to maintaining the distinctive red hue of the bricks. As a reducing agent, hydrogen can reduce the amount of oxidation that takes place within the kiln, and therefore potentially affect the final colouration of the brick product. To offset this, oxygen levels had to be carefully monitored and adapted during the trials, to ensure the renowned rich red hue of the final brick was maintained.

In order to run the hydrogen blend trials, Air Products provided a hydrogen storage facility and a pressure and flow regulation system.

Long term perspective

The impact of a hydrogen-enabled furnace on carbon emissions coud be, according to Manley, quite significant: “If we could operate a kiln on 100 percent hydrogen, we would be able to reduce our carbon output by 40-45 percent. That’s significant but there are opportunities with our mobile plants too, where the introduction of fuel cells could further reduce our carbon emissions by 8-10 percent. That means we could achieve a total reduction of around 55 percent of our carbon emissions through the introduction of hydrogen. This would help make Forterra an industry leader in decarbonisation.”

Michelmersh and HyBrick

Another leading UK brick producer, Michelmersh, has been busy too with hydrogen tests with HyBrick, a green-hydrogen-fired brick feasibility project, as they inform in a blog post from November 2024. The goal was to prove that hydrogen instead of natural gas could be used to fire clay bricks and retain the same technical properties. The aim was to reduce carbon emissions associated with clay brick firing by 60 percent or more.

The tests were conducted on Michelmersh’s best-selling product, Freshfield Lane First Quality Multi. Accordingly, the test-fired bricks were required to fufill the following criteria:

Compressive strength of more than 27N/mm2

Water absorption of no more than 12 percent

An F2: frost-resistant rating (suitable for all conditions)

Thermal conductivity of 0.51W/m*K

To controll the test results, control bricks were fired for under 20 cycles to ensure they met technical and aesthetic requirements and characteristics and to determine the baseline carbon emissions and product specifications using the hydrogen-ready burner.

HyBrick testing

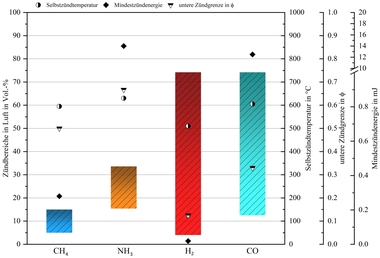

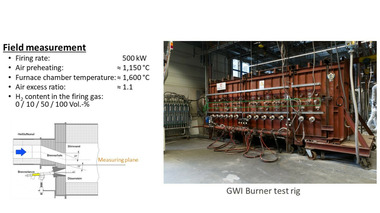

To conduct test hydrogen firing, Michelmersh retrofitted a small independent kiln used at its Freshfield Lane facility for special-shaped bricks. As well, it was ensured that the kiln could withstand the differences in flame temperature, burning speed and requirements for combustion air with higher levels of moisture, exert more control over the firing curve, and draw more oxygen in to create airflow. This required replacing burners, manufacturing a skid to reduce the hydrogen pressure, and other modifications to allow engineers to precisely measure and control the firing curve. Changing combustion from natural gas to hydrogen required adjusting the firing curve.

Michelmersh also took care of health and safety measures. The retrofitted kiln was used in a non-enclosed space, allowing any potentially leaking hydrogen to dissipate into the air, avoiding dangerous build-up. Multiple fail-safe devices into the skid to shut down the hydrogen flow if there was a leak were designed and installed. Furthermore, Michelmersh invested in numerous Hazard and Operability (HAZOP) studies, leak and flame detectors and an ultrasonic warning system alerting peoplea cross the whole site in case of a detected hydrogen leak or flame outside the kiln.

Michelmersh ran three firing trials using 100 percent green hydrogen as the fuel source.

Results and outlook

The results of the trial firing exceeded eepectations, resulting in an 81 to 84 percent reduction in carbon emissions over the three trial burns. Michelmersh is convinced that, with further trials and process optimisation, they could increase this figure. An even higher percentage might be achievable with on-site hydrogen production. As well, future trials could focus on making the process even more fuel efficient by optimising the firing curve further and experimenting with the drying process. Other variables that could be tested include the configuration of bricks inside the kiln to improve airflow and adding more oxygen to the kiln.

However, Michelmersh is quite clear toward the end of the blog post, that albeit the trials were successful, hydrogen is not set as the only possible avenue towards decarbonisation. Especially when considering important factors like the availability of green hydrogen in the near future. As the company states: “Before we commit to this alternative fuel source, we want to explore more opportunities for decarbonisation. Biogas, syngas, recovering recycled heat, and electrified kilns are all potential options. They may also be faster to rollout than green hydrogen, which is currently hard to produce at the scale needed to meet demand.“