“Green cracked gas as firing gas for clay brick

production” – decarbonization with ammonia as fuel

Brief presentation of the “Green Cracked Gas” project

In the research project “Green cracked gas for clay brick production”, the production of CO2-free masonry bricks with the use of “green cracked gas” was studied. The “green cracked gas” fuel consists of a mix of hydrogen, nitrogen and a small part of ammonia. The project was financed by the European Union within the framework of “Next Generation EU” initiative and supported by Germany’s Federal Ministry of Education and Research. A total of five project partners actively participated in the project. The main project findings are:

1. Decentralized ammonia cracking enables the production of a combustible ammonia-hydrogen mix (“green cracked gas”) from ammonia.

2. The use of “green cracked gas” permits CO2-free production of masonry bricks.

3. The masonry bricks produced within the scope of the project did not exhibit any qualitative defects.

4. The necessary limits for nitrogen oxide emissions during the combustion process (NOx) were not exceeded.

5. In future, green ammonia can be an economical alternative to natural gas firing in the clay brick and roofing tile industry.

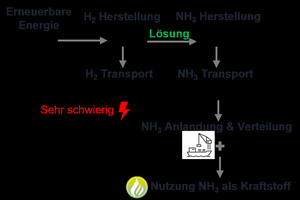

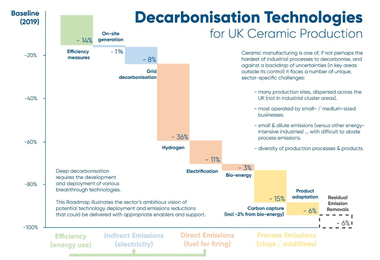

Ammonia as the energy source for the future

For a successful energy transition, amongst other things, a decarbonization of industrial process heat is necessary. “Green hydrogen” is often mentioned as a potential substitute for natural gas as a fuel for industrial burners. The production of green hydrogen requires high capacities of renewable energy. As these capacities are not available in Germany, the larger part of green hydrogen will be imported (e.g. from Canada, Australia or Saudi Arabia). Green hydrogen, however, is difficult to transport and the construction of pipelines to these countries is not foreseeable. The only possibility is therefore the import in the form of green ammonia with the following features:

Production from renewable power has been technically proven (green NH3).

Low-cost transport and storage in liquid form (compared with hydrogen).

Global distribution infrastructure.

No costly CO2 extraction from air like in the production of green hydrocarbons.

Decentralized ammonia cracking – production of hydrogen from ammonia at place of use

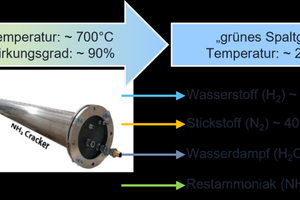

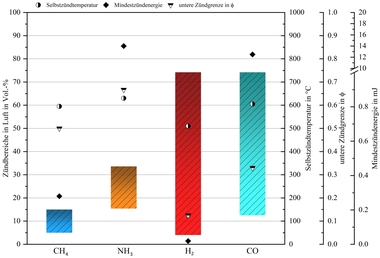

Ammonia is suitable as an excellent source of energy, but it exhibits a low flame velocity. For this reason, direct combustion of ammonia as the sole fuel is challenging. One solution is the use of a decentralized ammonia cracker, which cracks ammonia at the place of use. Besides hydrogen, the “green cracked gas” consists of the ammonia cracker comprising water, nitrogen and a small content of non-converted ammonia.

The green cracked gas is burned without further filtration and without intermedia storage directly after cracking in an industrial burner. A further application is combustion in piston engines.

Project content

The “Green Cracked Gas” research project ran over three years. The focuses were subdivided into individual packages, which were worked on by five project partners in close collaboration. The project content is as follows.

Development and testing of a burner for “green cracked gas”. To accommodate the higher volume flow of the cracked gas compared with natural gas, a natural gas burner was specifically adapted.

Development and testing of an ammonia cracker.

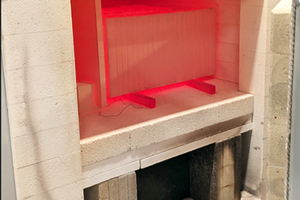

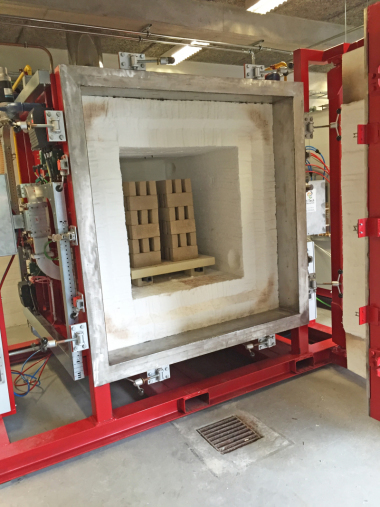

Development and testing of a pilot kiln, including CAD modelling.

Development and evaluation of a flow- and heat-related model for the pilot kiln.

Optimization of the airflow around the clay bricks in the pilot kiln based on modelling of the process.

Set-up of an adequately safe test environment for pilot kiln operation.

Firing of clay bricks (several batches) with “green cracked gas” in the pilot kiln.

Quality analysis and comparison with conventionally fired bricks.

Studies on the cost efficiency and environmental performance of the use of cracked gas for firing clay bricks.

Challenges and project results

The pilot kiln was equipped with the specially adapted burner and operated with a firing heat output of around 20 kW. The firing heat output in the burner was composed of around 90 % hydrogen and 10 % residual ammonia.

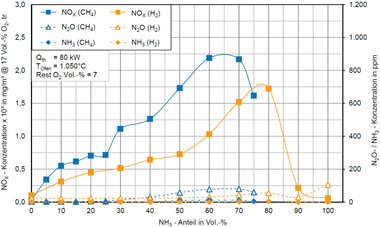

The burner was operated with cracked gas at a lambda value of almost 1.0. Natural gas burners are generally operated with a considerable air excess (lambda 1.05 – 1.3). In these operating conditions, for operation with cracked gas, high NO concentrations result in the flue gas, which easily exceed the statutory limits specified in Germany’s 44th Federal Immission Control Ordinance. For operation at a lambda value of 1.0, the statutory specifications were easily complied with.

Temperature monitoring, which was effected with 15 thermocouples in the pilot kiln, showed temperature differences up to 300 °C during the preheating process. The required final temperatures up to 1 000 °C were reached in the pilot kiln. After the maximum had been reached, the burner was switched off and the temperature differences subsequently balanced out. A total of 35 – 40 masonry bricks were fired in five batches with “green cracked gas” in the pilot kiln.

According to the factory test at Juwö Poroton, the masonry bricks fired with cracked gas fulfilled the parameters for product approval. The fired bricks did not differ from bricks that had been fired with natural gas in respect of their dimensions, failure load, compressive strength and density. The only difference was a lighter colour, which could be attributed to the lower lambda values during firing.

The software-based lifecycle assessment compared the bricks produced on ammonia basis with bricks fired with fossil natural gas. Basic precondition for CO2 savings is the production of ammonia with renewable energy (green ammonia). With the use of green ammonia, a considerable CO2 saving up to 70 % can be achieved, which is influenced primarily by the form of energy generation.

Similar to the environmental performance, the cost efficiency is influenced primarily by the development of green ammonia. For the import of green ammonia, reliable prices are not yet available. Key factor is the price of electricity estimated for the electrolysis for production of green hydrogen. The downstream processes for ammonia synthesis and for transport have been tested and are subject to fewer uncertainties.

Conclusion and outlook

The use of ammonia cracking and “green cracked gas” enables CO2-free firing processes for masonry bricks without any sacrifice of quality. Flue gas emissions must be taken definitely into account with regard to combustion of the gas. For a lambda value near 1.0, the statutory limits for flue gas emissions can be complied with.

In the coming years, green hydrogen will be imported to Germany mainly in the form of ammonia. With the direct use of green ammonia as fuel, complex and expensive storage as well as distribution of hydrogen are not required.

The unclear price forecast for the production of green hydrogen is the biggest uncertainty in the assessment of the overall cost effectiveness. In comparison with applications with green hydrogen, ammonia, however, offers solution approaches as an alternative to pipeline transport.

The first worldwide call for tender by the H2Global foundation established by Germany’s Federal Ministry of Economic Affairs took place in autumn 2024. The cost price for green ammonia from Egypt to Central Europe stood at 800 EUR / tonne ammonia (around 16 Ct. / kWh). The use of green ammonia is therefore only cost efficient provided there is a considerable reduction in price, which can be expected with a rise in the number of projects.

Ammonia offers immense potential as fuel to be a key alternative solution in the long-term energy transition. All aspects examined (firing process, ammonia cracking, flue gas treatment) offer considerable potential for optimization.

The overall project coordinator Stefan Jungk (owner of Juwö Poroton) summarizes the project findings as follows: “Ammonia can be used as fuel for the production of masonry bricks and presents an alternative solution especially for decentralized consumers without connection to the hydrogen core network. The project shows also, that ultimately the overall cost efficiency is key. The price of the energy source used is the most important factor. The substitution of natural gas in industry is a marathon, and Germany needs a clear strategy, specific projects and fast realization. Otherwise, neither the quantities required nor the target prices for green hydrogen or its derivatives will be achieved.”

Brief presentation of the project partners

As a family-run SME since 1862, JUWÖ Poroton-Werke Ernst Jungk u. Sohn GmbH stands for innovation and commitment to developing to clay brick’s leading position in Germany and Europe. The company is the biggest brick manufacturer in the Rhineland-Palatinate, Hesse, Northern Bavaria, and Saarland, and, at two sites with over 140 employees, it produces ecological and sustainable brick products, especially high-thermal-insulation clay blocks for residential and commercial masonry construction.

whs Gesellschaft für Energietechnik GmbH has been active in renewable energies since 1996. For further development of the ammonia cracking technology, Ammonigy GmbH was founded in 2020.

IBS Industrie-Brenner-Systeme GmbH supplies low-emission and energy-saving industry burners for high-temperature applications. In addition, the company supplies dryers, flue gas purification systems and processing equipment.

The Energy department of the Fraunhofer Institute for Microengineering and Microsystems IMM is developing catalytic converters and catalytic coatings for microchannel reactors. Moreover, the IMM is optimally equipped to simulate and test new systems and burners and assess processes.

The Fraunhofer Institute for Industrial Mathematics ITWM ITWM in Kaiserslautern uses modelling and simulation for the optimization of processes and products. Fluid dynamic design and high-temperature processes have played a prominent role for over 20 years.