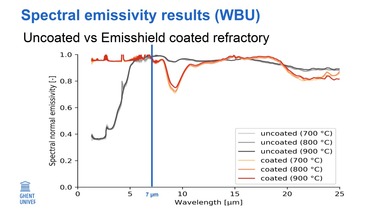

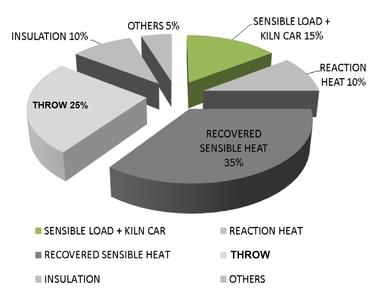

Strategic partner and certified installer for Emisshield Coatings with proven average energy savings of ±5% in more than 30 brick & tile kilns in Europe

Emisshield is an innovative high emissivity coating (HEC) technology, licensed by NASA, designed to enhance heat transfer and energy savings across a wide range of heat-driven industrial applications, ultimately boosting production efficiency.

Typically paying for itself within a year and boasting a product lifespan of 5 to 7 years, more than 30 roller and tunnel kilns across Europe have been coated over the past two years. These kilns serve various purposes, including the production of bricks, roof and floor tiles, flower pots, and refractory materials. Notably, the range of applications for refractory production is particularly challenging, given the extreme temperatures of up to 1650 °C that are reached.

Institute for Brick and Tile Research

In August 2020 the walls and ceiling of a batch kiln at the Institute for Brick and Tile Research in Essen, Germany, with an operating temperature of 1100 °C (2010 °F) were coated with Emisshield Ceramic fiber coating. A reduction of 6% in gas consumption was established and after 3 years of operation the coating is still fully intact.

After this successful testing of Emisshield’s HEC, the refractory coating gained significant attention from numerous customers throughout Europe looking for solutions to save energy and decrease CO2 emissions.

Refratechnik Ceramics GmbH

In early 2023, Refratechnik Ceramics GmbH from Melle, Germany, took the initiative and coated their first tunnel kiln with Emisshield. In addition to the standard coating suitable for temperatures up to 1300°C, a specialized coating tailored for temperatures reaching up to 1700°C was also employed. Encouraged by the positive outcomes observed in terms of furnace temperature uniformity and energy efficiency, Cress B.V., the designated application partner for Emisshield in Europe, was entrusted with coating another furnace. This subsequent application was successfully executed in February 2024.

Variety of Coatings

Our coating solutions encompass a diverse range, spanning approximately a dozen variants tailored to suit various sectors. From addressing the needs of the petro-chemical and metal industries to catering to a wide array of other sectors, our coatings are innovative and effective. Whether it’s for enhancing durability in Hard/Castable Refractory applications or optimizing performance on Ceramic Fiber Substrates across industries, we also offer metal coatings to meet further specific demandsof our clients.

±5% Proven average energy savings

<1 Year ROI

7 Years typical service life

0,85-0,95 Hemispherical emissivity