Energy Savings in Brick and Tile Kiln Cars

Abstract

In the industrial production of bricks and tiles, it is well known that the gas consumption required for firing the final product represents a significant cost and environmental concern. Reducing this consumption is key to improving competitiveness and sustainability.

Often, this consumption is not optimized due to factors such as excessive heat loss through kiln walls or inadequate insulation in kiln cars. At TEIDE REFRACTORY SOLUTIONS, we offer simulation studies using Finite Element Method (FEM) analysis to identify potential energy savings in tunnel kiln cars.

A customized script has been developed to assess the thermal limits and mechanical stress on materials throughout the firing cycle. These simulations help predict premature refractory failure and guide design improvements.

Methodology

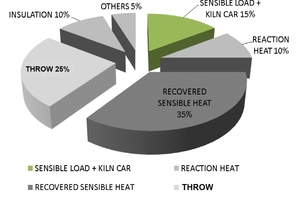

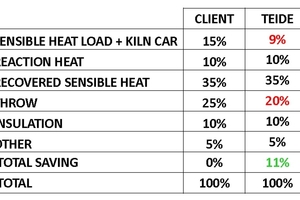

End users typically lack access to the full energy balance of their kiln processes, as this data is usually proprietary to the kiln manufacturer. Leveraging our expertise in refractories, we have compiled a validated energy balance for a standard tunnel kiln to serve as a benchmark. (»Fig. 1)

The most critical area for energy savings is the kiln car. We simulate and evaluate the temperature distribution across layers and the cold face of the car during the entire cycle. We compare the heat accumulated in the client’s existing car with our optimized proposal, and based on the findings, we recommend design improvements.

Since each client operates under specific cycle, temperature, and load conditions, we tailor our energy optimization strategies accordingly. Our simulations provide the technical justification for investing in improved kiln car insulation.

Case Study

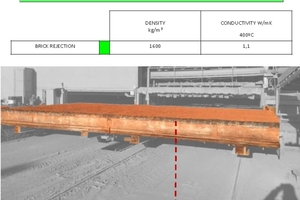

To reduce manufacturing and maintenance costs, a client self-produced kiln cars using semi-insulating concrete with a density of 1.6 kg/m³ and thermal conductivity of 1.1 W/m·K (at 400 °C).

Operating conditions included a 13-hour cold-to-cold cycle, 1000 °C peak temperature, and a load of 1300 kg/m². The client specifically required solid top plates to prevent product loss and premature plate failure.

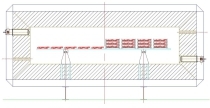

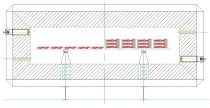

We compared the client’s original refractory configuration with our proposed design using FEM simulations.

Design and Simulation

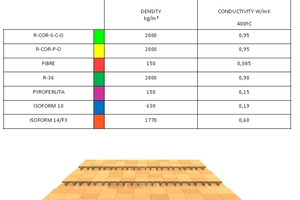

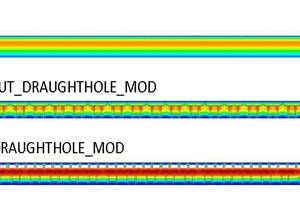

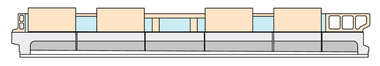

We conducted three simulation scenarios: the original client kiln car, a TEIDE design without fire paths, and a TEIDE design with fire paths. Results show that the TEIDE design with fire paths reaches higher exit temperatures, indicating better insulation. (»Fig. 2, 3, 4)

Although the customer’s current kiln car reaches a lower temperature in its hottest zone (350 °C) compared to our proposal (475 °C), its average density in that zone is significantly higher: 1.6 kg/dm³ compared to our design’s 0.15 kg/dm³ in the highest temperature zone.

This contrast highlights the relevance of adapting the design of the kiln car to the real thermal profile of the working cycle, since an optimised configuration allows a significant reduction in the energy consumption associated with the kiln car, since if the accumulation of more temperature at the kiln exit is focused on less dense places, the heat accumulated in the kiln car will be lower.

Temperature evolution across layers and the bottom of the car was also analysed, confirming improved insulation and lower energy losses (»Fig. 5). This reduction translates into a measurable decrease in energy consumption and a potential 11% savings — a compelling argument for upgrading the entire fleet of kiln cars.

As shown in the temperature progression graph, the curves ending at 139.0 °C and 100.3 °C reflect the thermal behaviour beneath the kiln car. These lower temperatures indicate improved insulation, leading to reduced heat loss and, consequently, lower energy consumption.

The following table »Fig. 6 summarizes the impact of the proposed design on the initial energy balance. A savings of 11% in energy consumption can justify the investment in retrofitting the entire fleet of kiln cars.

Simulation of Temperature Limits

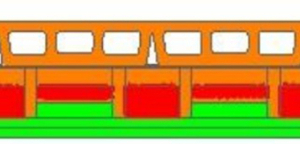

We developed a visual script to analyse the maximum temperatures experienced by each component of the kiln car throughout the firing cycle. This tool is especially intuitive, even for users with non-technical backgrounds.

The results below (»Fig. 7) use a color-coded scale to indicate how close each component gets to its classification temperature. Red zones suggest the insulation is approaching fusion risk, indicating potential premature failure in service.

Thermal Shock Simulation

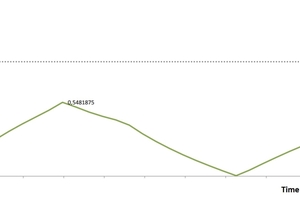

To assess fracture risk in refractory components, another script was developed to identify pieces susceptible to thermal shock, particularly those with partial exposure. Internal stress is evaluated, and if it exceeds a predefined threshold, the part is at risk of early failure.

The graph below (»Fig. 8) displays internal stress over the cycle. If the green line surpasses the dashed threshold, it indicates a risk of premature breakage. These insights allow us to redesign the geometry or select a more suitable refractory grade to withstand the service conditions.

Conclusions

Simulation tools are essential for developing optimized and durable kiln car designs tailored to the customer’s specific cycle and temperature requirements.

With our current toolset, we can analyse energy savings, temperature profiles across the refractory layers, and thermal behaviour beneath the kiln car. The newly developed scripts for temperature limit visualization and thermal shock analysis offer added value by enabling predictive design validation.

These innovations ensure that each kiln car solution delivers long-term energy efficiency and structural integrity.