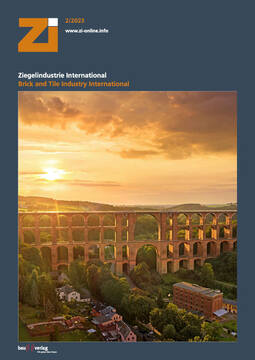

The largest brick bridge in the world

The largest brick bridge in the world, the Göltzsch Viaduct, is located in the Vogtland region of Saxony, Germany. The railway viaduct spans the river valley of the Göltzsch, a tributary of the White Elster. The arched bridge is 574 metres long and 78 metres high. Built in the middle of the 19th century, it is one of the oldest testimonies to railway history in Germany.

Planning phase - the first statically calculated bridge

Bridging the Göltzsch valley was one of the greatest challenges in building the railway line from Leipzig to Hof. On the one hand, the width and depth of the valley exceeded all previous experience in railway construction. On the other hand, generally applicable static calculation methods were not yet known. In 1845, 81 proposals were submitted to a competition with a prize money of 1000 talers. However, none of them met the requirements. Proof of the load-bearing capacity of the designs was not based on calculations, but mostly on the experience and individual assessments of the designers.

The head of the review board, Professor Johann Andreas Schubert, then developed a proposal based on four of the submitted proposals and his own experience with mathematical methods for structural calculations. In doing so, he relied on a new calculation model, the so-called support line theory. The viaduct built according to this design can be considered the first bridge ever to be calculated according to mathematically sound structural principles. The plan was for an arched bridge consisting of evenly spaced individual arches on four levels.

The decision to use brick as a building material was made for reasons of cost. Natural stone such as granite was not available in sufficient quantities in the vicinity of the construction site. On the other hand, there were rich clay deposits there, so that bricks could be procured more cheaply and quickly. Schubert subjected the bricks used to random compressive strength tests with an apparatus he developed himself. Natural stone was used in some places with particularly heavy use.

Building with bricks in the Dresden format

The foundation stone was laid on 31 March 1846. Due to technical challenges, the plans had to be changed when the foundation work began. For example, the ground in the valley proved to be less solid than assumed. For the foundation of the central pier, 15 metres were dug deep without reaching load-bearing soil. Consequently, the senior construction manager Robert Wilke decided to do without the foundation and the pier. To this end, two of the planned arch openings were replaced with a single large arch with a span of 31 metres. The striking appearance of the bridge is based on uncertain ground, so to speak. For structural reasons, the two central arches were designed as basket arches, not segmental arches.

The construction work was very expensive. Between 50,000 and 150,000 bricks were fired daily, transported to the construction site and laid. Bricks in the Dresden format (11 ¾ inches x 5 ¾ inches x 2 ¾ inches = 27.73 cm x 13.57 cm x 6.49 cm) were used. Almost 20 brickworks were engaged in the production. Up to 1,700 workers were employed on the site. Inadequate safety precautions encouraged accidents: 31 workers died, more than 1,000 were injured. For the falsework that supported the arches, 23,000 trees were felled. A total of around 26 million bricks were used until completion in 1851.

The structure was inaugurated on 15 July 1851, and the first trains crossed the bridge on 16 July. It is still in use today, carrying modern high-speed trains such as the ICE, which weigh considerably more and generate greater dynamic traffic loads than steam locomotives of the time.