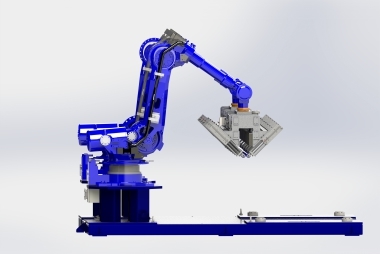

Wienerberger Berca: Robots Everywhere! A modern, high-performing factory without conventional grippers or dryer car loading systems

At the Wienerberger Berca Plant, SABO delivered a cutting-edge robotic handling solution that entirely eliminates the use of conventional grippers and conventional dryer car loading/unloading mechanisms. In this line all the positions for loading or unloading products or dryer frames have been implemented with the use of robots. The result is a flexible, productive and future-proof facility, capable of handling a wide variety of brick formats with minimal downtime. During the previous years, many of the loading and unloading positions have been implemented with robots but it is the first time that SABO Engineers in close cooperation with the Engineering Department of Wienerberger, decided to use robots in all positions.

The production line begins with the loading of green products right after the electronic cutter. This task is performed by a robot equipped with interchangeable grippers, allowing seamless switching between different formats. The loaded frames are then handled by robots using fork-type grippers, which replaces the traditional multiple-fork systems previously used to load or unload dryer cars.

These conventional fork mechanisms were often large, mechanically complex, and required extensive installation and maintenance time. Their elimination brings a more flexible, responsive and efficient production flow. The robotic loading and unloading of dryer lathes also resulted in implementing smaller buffer elevators, which further decreased installation time and costs.

Further down the line, a dedicated robot handles the feeding of empty frames into the dryer lath transportation, replacing the conventional gripper previously used for this task. This not only simplifies the layout but also enhances flexibility and reduces maintenance of the system.

On the unloading side, robots take the dried bricks from the frames and place them into kiln cars, but not before they pass through a modern programming station with servo motors that rearrange the bricks into the correct configuration for kiln loading with great precision.

This full robotic approach delivers a number of key advantages:

Fast installation and commissioning

High adaptability to product changes

Low maintenance and downtime

Consistent and precise operation

Significant productivity gains, even with a wide range of formats

In fact, the Berca plant produces over 20 different types of bricks, and format changes are now quick and effortless — a task that once required significant time is now completed in just minutes. Combined with the benefits of the fully robotic automation and its minimal downtime — only 1–5% per shift — the end result is a highly efficient and productive factory.

This project reflects SABO’s commitment to offering solutions that combine reliability, practicality and easy maintenance, using top-tier components from trusted manufacturers like Festo, SMC, SEW, Siemens, Fanuc and others.

As always, SABO supports its customers to achieve their business goals, ensuring that innovation comes with robust support and real-world performance.