Comparison of designs and economic efficiencies of air circulation systems in dryers (Part 1)

In remembrance of Dr.-Ing. Karsten Junge

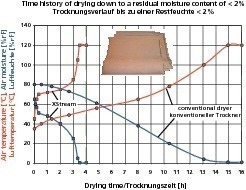

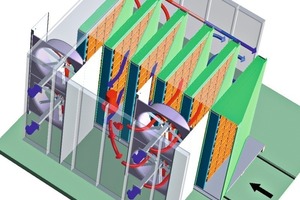

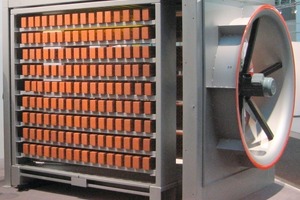

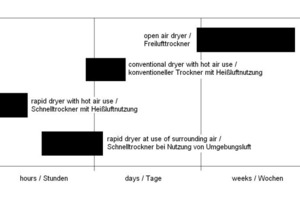

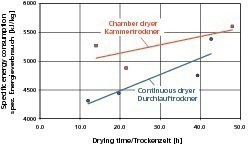

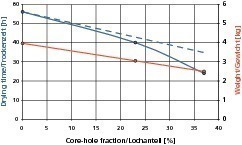

In a convection dryer, such best-achievable economic indicators as heat and power consumption and the requisite installation space depend on the quality of the air circulation system. In German speaking areas, the two most frequently encountered types of air circulation systems for conventional dryers are rotary fans and airwalls. At the same time, more and more rapid drying processes are becoming established. The present contribution compares and analyses the measured economic operating data of the various air circulation systems. This first part deals primarily with data pertinent to masonry bricks and clinkers, while Part 2 (coming up in Zi6/2011) will present corresponding data for roof tiles. In nearly all regards, rapid dryers emerge as the most economical variant, often by a wide margin.

1 Introduction

All over the world, bricks of all shapes and sizes are being made of widely disparate clay raw materials [10, 29]....

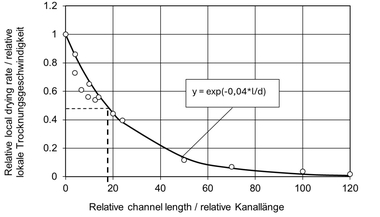

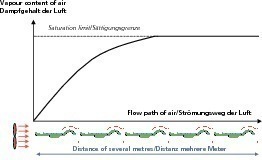

![»13 Relative drying rate as a function of relative length of flow channel acc. to [13] and own investigations](https://www.zi-online.info/imgs/tok_a42f2c0f925a790882bd52b51eda6380/w250_h146_x125_y73_101466102_a581aa0c28.jpg)