Resource efficiency in the clay brick and tile industry

Part II: Recycled clay from the washing of variegated sandstone

1 Geological frame and location

At Untschen Gravel Works near Gera, Germany, severely weathered clayey and pebbly sandstone is extracted and processed to road construction materials. In the processing and mineral washing of the rock, considerable volumes of recycled clay is produced in the form of filter cake. The gravel works is located in the district of Altenburger Land in Thuringia and well connected via the A4 motorway. Geologically the site lies in the outcrop of the eastern outer plateau zone of the Thuringian Basin. In lithostratigraphic terms, the exposed strata sequence is classified as part of the basal conglomerate of the Lower Triassic. The material was sedimented around 250 mill. years ago in continental-arid climatic conditions. At the turn of the Cretaceous/Paleogene around 65 mill. years ago, the strata were exposed to intensive tropical-subtropical weathering. This caused partial replasticization of the clay minerals.

2 Mineralogical composition

The filter cake exhibits a well-graded grain size distribution with an average ultrafine content of d < 2 µm = 36 mass %. The content d > 63 µm averages 8 mass %. In respect of the mineral phases it contains, the filter cake is characterized by a significant phyllosilicate content with ∑clay minerals = 61 mass %, illite/mica dominating before disordered kaolinite and low content of mixed layer minerals. White mica is not only found in the clay fraction but over the entire particle size range up to visually recognizable biaxial mica flakes. In the series of the crystalline weathered remains, quartz dominates before potassium feldspar. Most of the iron is present in the form of goethite. Accessorily, jarosite is detected as a secondary reformation. In respect of the element distribution, silicon dioxide dominates clearly before aluminium oxide and iron oxide. The flux regime is dominated by alkalis, especially by the potassium from the white mica minerals. The content of organically bonded carbon TOC amounts to 0.25 mass %.

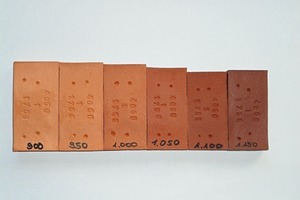

3 Ceramic technological characteristics

The filter cake is characterized by a stiff-plastic consistency and is ideal for processing in conventional brickworks preparation plants. It exhibits medium-plastic properties and presses well. Owing to the low content of innercrystalline expandable clay minerals, increased sensitivity during drying and in the preheating zone of the kiln is not expected. On account of the high potassium oxide content in the entire grain size range, the material is very reactive in the firing process and starts sintering early on. This is reflected in the high linear firing shrinkage and the low water absorption of the fired body. Accordingly, the material has limited refractoriness. From peak temperatures of around 1100° C, the material releases oxygen as a result of the decomposition of iron minerals and also tends to boil. Owing to the high content of goethite, an intensive-red fired colour with strong colour effects is obtained in reduction firing. Preferred use is in the production of facing bricks and clinkers as well as in the production of high thermal insulation clay blocks. No experience in the roofing tile sector is available as yet. Technical recommendation: use as a medium-plastic sinter-active additive in a batch content between 10 and 30% depending on the peak temperature, the reactivity and the refractoriness of the body. Suitable for intensifying the colour of red-firing bodies.

4 Volume availability and final remarks

The filter cake is produced during the permafrost-free months. The available annual volume depends on the volume of the primary rock processed and totals up to 40 000 t. To bridge the winter months, a stockpile with around 20 000 t filter cake is available.

The data given are only guide values and subject to natural fluctuation. All information is not legally binding.