Resource efficiency in the clay brick and tile industryPart III: Recycled kaolin from silica sand washing

1 Geological background and site

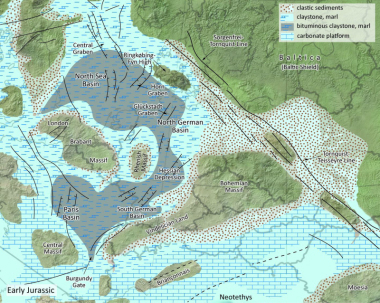

For over 135 years, the family-run company Strobel Quarzsand GmbH has been extracting kaolinitic silica sands and processing them to high-quality raw materials for the glass and construction chemical industries. The silica sand plant is located north of Amberg in the Upper Palatinate, Bavaria. Geologically, the deposit lies in the outcrop of what is known as the Dogger Sandstone, which can be attributed to the Brown Jurassic, especially the Dogger beta. The formation of the silica sands goes back to delta-like coastal deposits around 170 mill. years ago. Starting from crystalline source areas from the area of the Bohemian Massif, the fine-grained silica sands were deposited together with kaolinitic fines in a thickness of just under 100 m. The deposit reserves total around 150 mill. tonnes. On account of the generally low iron content, whitish grey sediment colours dominate. On a minor scale, there are yellowish as well as pinkish red to intensive red colours. During washing of the silica sands, the fines < 40 µm are deslimed and dewatered on modern membrane filter presses to a residual moisture content of around 20 mass %. Here considerable quantities of kaolin filter cakes are produced as a recycled product with long-term assured supply. The filter cake has a plastic consistency without any problematic coarse components, impurities or organic substances.

2 Mineralogical composition

The filter cake has a well-graded particle size distribution with an average fines content of d < 2 µm = 39 mass %. The content d > 63 µm averages 20 mass %. In respect of the mineral phases contained, the filter cake features a considerable phyllosilicate content with ∑ TM = 50 mass %, well-ordered kaolinite significantly dominating compared to illite/mica. Innercrystalline swelling clay minerals are not detected. With regard to the series of crystalline weathering residue, quartz is the only phase. Iron is present as an accessory phase in the form of haematite. In respect of the element distribution, silica dominates clearly in front of alumina and iron oxide. The filter cake has an exceptionally low content of alkaline and alkaline earth flux. Potassium dominates with 0.38

mass % in front of magnesium with 0.1 mass % and calcium with 0.07 mass %. Sodium is below the detection limit of 0.03 mass %. The content of organically bonded carbon is also very low and amounts to TOC = 0.09 mass %.

3 Ceramic characteristics

The filter cake is characterized by a soft to stiff plastic consistency and can be used in conventional brickwork preparation plants. It exhibits slightly plastic properties and can be dried without any problem. In the firing process, the filter cake first demonstrates an exceptionally low release of OH groups from adsorption and interlayer water. Up to a range of around 400° C, the material is therefore very firing-insensitive. Typical for the content of kaolinite are the clear endogenous peak of the water of crystallization at 533° C as well as the exothermal reformation reaction at 990° C. Already at around 700° C, the maximum weight loss of 5.7 mass % is reached, all degassing having been completed. On account of the low content of flux, the filter cake has an extremely wide sintering interval and only starts sintering at a late stage. This is reflected in a very high refractoriness and correspondingly low linear firing shrinkage, which only starts at around 1100° C with 0.2%. The water absorption of the fired body varies depending on the peak temperature between 17.4 mass % at 900° C and 15.4 mass % at 1150° C. On account of the low content of haematite, the fired colours range from pink to cream, the fired colour becoming lighter with increasing peak temperature. Owing to the very low thermal conductivity of the body of 0.24 W/mK, its main use is in the manufacturing of high thermal insulation backing bricks. Practical experience in the roofing tile sector has been available continuously since 2003. Use in the production of facing bricks and clinkers is also easily possible. It can be used as a slightly plastic additive with a batch content of 10 to 30% to increase the content of the medium grain and improve refractoriness as well as to lower the thermal conductivity of the body in backing brick bodies. It is also suitable for lightening the colour of red-firing bodies.

4 Volume availability and final remarks

The filter cake is produced throughout the whole year without any winter break in two heated press facilities. The available annual volume currently amounts to over 80 000 t. The specified data are only guide values and are subject to natural fluctuations. This information is not binding. Supplementary details are available for download here .