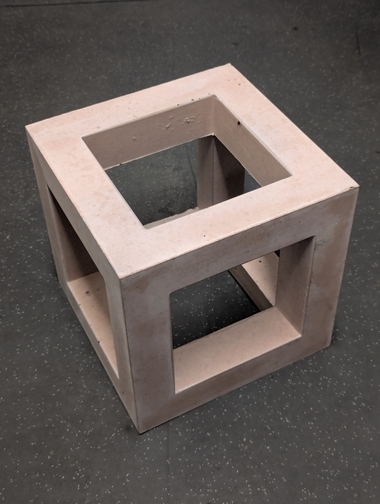

A second life for bricks

Due to the increasing scarcity of materials, it is becoming more and more important for players in the construction industry to act in a resource-conserving manner. In order to make optimal use of raw materials, manufacturers should ideally ensure a closed-loop recycling system for their products. In 2020, the Leipfinger-Bader group of companies (Vatersdorf) succeeded in doing this when it commissioned its recycling plant, which it had developed specifically for this purpose, at the Puttenhausen plant site near Mainburg (Lower Bavaria). Now the family-owned company is drawing up a gratifying interim balance: thanks to the innovative plant, more than 5,000 tonnes of broken bricks have been recycled in the meantime. While sorted insulating materials are reused in production, the crushed broken bricks are used again, for example, in potting soil mixtures.

Construction and demolition waste is responsible for a large part of the total waste produced in Germany. However, the Leipfinger-Bader Group has been demonstrating since 2020 that, for example, mineral construction waste does not always belong in a landfill: „With the help of our recycling plant at the Puttenhausen site, we have now been able to recycle over 5,000 tonnes of broken bricks. This means that the plant, which is the result of intensive research work, clearly exceeds our expectations. We are thus setting another example for more climate protection and sustainability in our industry,“ says company boss Thomas Bader happily.