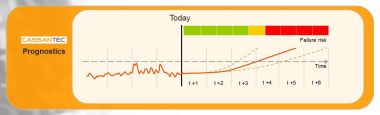

Condition monitoring for production-critical drives and fans

Against the background of Industry 4.0 and the increasing requirements for plant availability, it is important to know about the condition of a plant. If deviations from set conditions are detected, countermeasures can be implemented, or the remaining service lifetime predicted.

Prototypes of the innovative Keratek Turboblock circulating system were already equipped with data storage to record bearing and medium temperatures. In the second generation of the system, monitoring of machine vibrations was added. These many years of experience are now being channelled into a retrofit solution for already installed and new plants.

Modern analysis devices and data loggers allow plant operators to capture and display live data and assess historical values, for instance by means of visualization or an app on a smartphone. For instance, initial damage to bearings or impurities on fan wheels can be detected. The development of such systems and services is being expedited by Keratek together with Aliba Maschinenbau GmbH and its experts on vibration analysis.

In this paper, the necessary components and the analysis software are presented. The integrated technical concept consists of several modules, which can be implemented step by step.

Christian Gäbelein, Keratek GmbH

Dominik Delic, Aliba Maschinenbau GmbH