Dear Readers

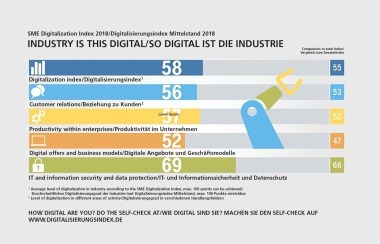

Since panic mongering never helps, we are sticking to what we do best: compiling an interesting issue for you, this time with a focus on digitalization. No industry can afford to ignore this development, regardless of its size or orientation. The study “Digitalisierungsindex Mittelstand 2019/2020”, (SMEs Digitalization Index 2019/2020) conducted by techconsult on behalf of Deutsche Telekom revealed that the majority of companies are convinced that they can only remain competitive with digital transformation.

Even the digitalization of certain processes can bring time and cost savings, while many can’t yet imagine what end-to-end digitalization of industrial engineering and production processes can achieve. Companies that invest in digitalization report increased turnover, easier acquisition of new customers and an improvement in value creation. But small companies are still very hesitant in their approach to digitalization. Most of them don’t have the digital competence in-house and often lack the funds for external support. However, not addressing the issue of digitalization carries the risk of being cut off from growth. Support can be obtained from the many new start-ups that are developing new IT solutions and bringing them to market in order to develop new products and business models.

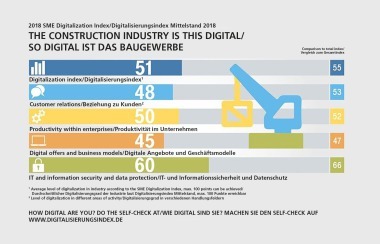

The construction industry lags behind when it comes to digital change – and this is having an impact: While the productivity of the German economy has risen by 11 % over the last ten years, in the construction industry it has just scraped 4 %. Starting on page 20, Prof. Christian Glock, Department of Civil Engineering at the Technical University of Kaiserslautern, explains to us why digitalization can drive productivity for the construction industry.

Our report starting on page 24 looks at how the medium-sized clay brick and concrete supplier August Lücking in Warburg-Bonenburg is engaging with digitalization. The new management generation at the company is working systematically on digitalization and developing solutions, some of which can also be adopted by other clay brick and tile plants. The study “Digitalisierungsindex Mittelstand 2019/2020” advises especially smaller companies to network with digital pioneers via platforms in order to be able to successfully realize projects themselves.

Stay healthy!

Yours

Anett Hümmer

Editorial office of Zi Brick and Tile Industry International