Digital printing on clinker bricks – is it catching on?

Not so long ago, it was the tile industry, especially porcelain stoneware, which used digital printing machines to present its products with a variety of new looks. In the meantime, the facing brick industry is also testing this possibility, and the first projects have already been realized. Digital printing offers the possibility to bring completely new designs to the market.

What is it: Tile or wood?

Using the example of wood optics, it is easy to understand what this change has brought for tiles. While the first attempts with digitally printed wood decors were not taken seriously, the tile has now matured into a serious competitor for the wood industry in the flooring sector.

On the development side, in addition to the haptic experience thanks to stronger reliefs and the adaptation of typical wood formats, a lot has also happened here. One example are digitally specialized graphic designers who have found their way into the development departments. Digital printing has influenced the value chain in many areas. Any kind of materiality can be applied in only one printing process. Production changes can be handled more flexibly with digital printing. Make-ready times on the production lines have been shortened considerably.

Digital printing for porcelain stoneware – a blueprint for the heavy clay industry?

This question can be answered with yes and no. From a design point of view, the tile has always been a very creative product – colourfully glazed, decorated using rollers or digitally printed. Often following the trends of architecture or textile fashion, the tile impressively reflects what digital printing can achieve. Natural stone, rough-sawn wood or abstract HD graphics – for the tile this is no problem in terms of observer acceptance. It does not lose its authenticity when the ceramic structure recedes into the background. But does that also work in heavy clay?

A similar journey could be in store for the facing brick. Unlike the tile, however, it stands for a certain kind of materiality with which it is perceived and often referred to – the “brick“. This rough, hard material has a high recognition value owing to its characteristics and the way it is processed.

If you look at the repertoire of different clinker brick manufacturers, you will only come across a few design approaches that do not want to be perceived as stony-sandy. Regardless of formats, colours, contrasts or whether rough or smooth – the clinker brick has so far remained true to its basic appearance. This is partly due to the technological conditions, which have so far made it almost impossible to question the appearance of the clinker brick in its entirety. The probability that digital printing will give new impetus to other views on the design of future facing bricks is therefore a question of “when“ rather than “why“.

New graphics, adapted to the heavy clay industry

The decor studio nukava, based in northern Germany, is already intensively engaged in this aspect and is in close contact with suppliers and manufacturers in the industry. Graphics must not only be reimagined, but also adapted to the production conditions in the heavy clay industry. As the nukava design team is closely interwoven with the ceramic industry, they know what is technically feasible and what is not.

nukava already offers a portfolio of digital designs that pick up on the typical clinker character, thus enabling manufacturers to continuously reproduce the special characteristics of a clinker series requested by customers. In addition, there are also new atypical decors which irritate the familiar eye with materials such as marble or wood structures, but which have a harmonious effect in themselves. Here, the observer has to engage with a new variation. If architects and planners know the possibilities of digitally printed clinker brick façades, this will change the market.

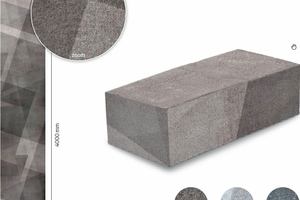

Another variation is the combination of material surfaces borrowed from nature and cleverly added graphic elements. These bring familiar and new ways of seeing into harmony. The NIA series is an example of what a new generation of facing brick series can look like. Viewed from a distance, NIA resembles high-contrast clinker bricks, which are already being used in modern architecture. If you get closer, you can see the graphic pattern of rectangular surfaces overlapping in different shades of grey. Only on closer inspection does it become clear what digital printing can achieve.

nukava – new digital coverings

www.nukava.com