Investing heavily in energy and environmental engineering, Leipfinger-Bader, the medium-sized clay brick manufacturer based in Vatersdorf, Germany, is taking a new approach to heat recovery. Following on from the previously installed two-tower system, the company has added a three-tower system with an additional heat exchanger. It was commissioned on 29 May by Dr Marcel Huber, Bavaria’s Environment Minister.

The new energy and environmental technology at Leipfinger-Bader has been individually adapted to the company’s needs. The exhaust air purification also meets future requirements for environmental protection while enabling effective utilization of the thermal energy. The regenerative thermal oxidation system (RTO) consists of three heat exchanger blocks combined on top of each other to form one unit. With cyclic switching, raw and clean gas flows through these blocks alternately. The raw gas is cleaned in a combustion process after the exhaust air has been heated up. Once it has cooled down, the clean gas leaves the system. During the process in the first two chambers, the third part of the exhaust air system is flushed through to ensure consistently high efficiency.

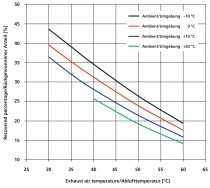

The real innovation of the system consists in the special combination of the heat recovery and exhaust air purification system. Thanks to an additional heat exchanger, the process heat that becomes available as a result of the cleaning process can be utilized. The clean gas flows through the heat exchanger block and gives off the thermal energy to the cold fresh air that flows through the pipes of the heat exchanger. The generated thermal energy is used in production for drying the Unipor masonry bricks. In this way, the new system guarantees a win-win situation in terms of energy gain: it no longer requires any fossil fuels for its own operation and at the same time gives off process heat that can be used for drying. With the introduction of the new system, Leipfinger-Bader expects to save over 90% fuel oil in its continuous dryer. The total fossil fuel saving corresponds around 35% of the previous consumption. “With the new energy and environmental technology, we are well-equipped for the future and at the same time we are recovering energy that would otherwise go unused. With an anticipated efficiency of 90%, we therefore reckon to obtain around 1 200 kW/h”, explains Managing Director Thomas Bader. The company also expects to reduce CO2 emissions by 2 500 t/year.