1 Initial situation and problem description

More than half of the energy used in the production of clay bricks and tiles is currently used for drying green bricks and tiles. The hot air needed for convection drying is supplied by the kilns in the brickworks or tile factory. In the cooling zone of the tunnel kilns operated there, hot air is generated, the enthalpy of which is in the same order of the energy needed for drying the green bricks and tiles. While very early tunnel kiln concepts further heated the hot air produced in the cooling zone with fuel in the firing zone, in order to use it for heating the green bricks in counterflow heat exchange in the preheating zone, around 30 years ago a departure was made from this concept. This can be explained by the fact that with the burner equipment in extensive sections of the preheating and firing zones, it was possible to homogenize the temperatures and kiln gases over the cross-sections to a previously unknown extent and thereby multiply the kiln throughput while improving product quality. This necessitated, however, the discharge of the heated cooling air from the tunnel kiln, as the operation of preheating and firing zone was now similar to that of heating furnaces and the basic principle of the tunnel kiln was abandoned.

It was only in recent times that high-temperature air circulators have been developed, which ensure extremely efficient circulation of the kiln gases at low cost, durably and at only low operating cost, therefore making all the front burners – mainly high-velocity burners with the primary task of emitting a high pulsed flow into the kiln chamber – dispensable. Insofar extraction of the cooling air, apart from a limited residual quantity, is no longer required. And there is no longer anything preventing us tackling the biggest energy consumer in the clay brick and tile industry, that is the drying of green bricks and tiles.

2 Objectives and solution strategies

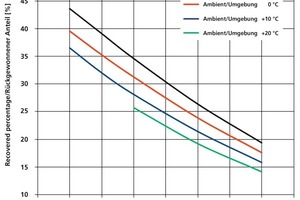

The concluded research work is concerned with various possibilities for substantially lowering the energy required for drying. Here the radical strategy of using outdoor drying and its technologically sophisticated modifications were expressly excepted and addressed in another, follow-on project. This project concentrates more on how the energy requirement can be lowered with existing drying technology. This refers initially to the commonly used chamber dryers, which can be operated at the unusually high supplied air temperatures currently in the clay brick and tile industry and therefore reach energy savings up to 30%. But it also refers to continuous dryers in which the process requires the extraction of the exhaust air where it has the maximum load of water and therefore at least does not cause any great loss on account of unacceptably low partial utilization of the water absorption capacity. Here too the temperature of the supplied air and that of the ambient air play a key role for the energy requirement.

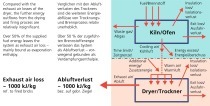

Based on the knowledge that the dryer exhaust air is by far the biggest energy consumer in the brickworks, it is logical to give consideration to the utilization of the exhaust air, and especially to recovering the heat from the dryer exhaust air. If the temperature of the exhaust air in the heat exchanger is lowered, it falls below its dew point, and mist and droplets or condensate form at the surfaces of the heat exchanger. This is connected with the recovery of the evaporation enthalpy used for water evaporation. In passive heat exchangers, however, the heated fresh air cannot have higher temperatures than the dryer exhaust air.

This is only possible with active heat recovery with heat pumps and similar equipment. For this purpose, the IZF proposed a turbine in which almost saturated dryer exhaust air is relaxed, for example, to a third of the normal air pressure and, connected with cooling caused by this, large quantities of its water vapour condense. After removal of the water, the same air is re-compressed, the relaxation and the compression, for example, running with turbines on a common shaft. With the compression, the previously relaxed and rained-out air reaches a very high temperature level. This process is based on the foehn effect known from meteorology, in which moisture-laden air rains off as it ascends high mountains and only cools very slowly, while, as it descends – now dry – it is heated much faster and leads to the foehn weather conditions typical for the foothills of the Alps. Such a process can be calculated with methods of technical thermodynamics. The results are very interesting and indicate ways for effectively saving drying energy. These are, however, associated with comparatively high investment costs, although with the further increase in energy prices, this should, however, not be any insurmountable hurdle.

3 Implementation in the field

As field contacts and measurements in the course of this research project have shown, the implementation of the various steps proposed here is currently very slow as kiln exhaust air is currently used to fully supply dryers in practically all brickworks. In light of the typically 30-years “life expectancy” of tunnel kilns, it can only be assumed that kiln-internal utilization of cooling air will dominate compared to cogeneration only in the long term and only then will a large number of brickworks operate their dryers more or less independently of the tunnel kilns. Then the steps proposed here will lead to convincing success!

This project was conducted by the Research Alliance of the Brick and Tile Industry Regd (FGZ). Under project number AiF 15031 N, it was funded by the Federal Ministry of Economics and Technology (BMWi) through the German Federation of Industrial Research Associations “Otto von Guericke” Regd (AiF) and implemented by the Brick and Tile Research Institute Essen Regd (IZF). The purpose of the research project was achieved. For a handling fee, the 99-page final report is available from the Research Alliance of the Brick and Tile Industry Regd in Berlin.