Pallet labeller AP182

GS1-compliant pallet identification

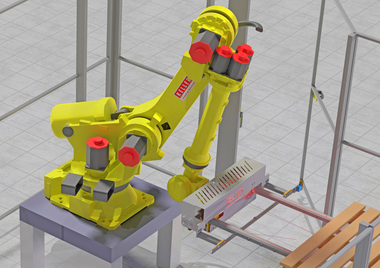

The highly compact system marks pallets by means of a dispensing stamp that can be moved over three axes. User-programmable traverse paths not only enable GS1-compliant pallet identification on the front and side in a single product stop, but also the labelling of two labels next to each other on one side. In addition, the three-sided labelling of pallets (front, side, back) is possible in only two conveyor system stops. The labels can be applied, either at a short distance by an air blast and/or by direct contact of the stamp plate with the product surface. The three-sided labelling is particularly interesting for block storage. Thanks to three-sided labelling, at least one labelled side is always visible, regardless of the pallet‘s position in the block.

Flexible, safe and user-friendly

The AP182 is a very innovative machine with a high rate of production and extreme flexibility. The labeller uses its own sensors to find the pallet surface independently. The flexible positioning programs help it to label the correct side. The programs for each label can be changed as required. Pallet throughputs of 120 per hour for two-sided labelling and 90 per hour for three-sided labelling are possible.

Due to its design, the AP182 is safe in terms of the Machinery Directive (applied standard EN415-10). It requires neither protective fencing nor protective enclosure and thus reduces the effort required for integration into the customer‘s plant. An automatic shutter and complete enclosure protects the system against production dust and other adverse environmental conditions. The label roll is placed at an ergonomic height and is easily accessible through large operator doors. For long-term, uninterrupted production, label roll holders of up to 350 mm are provided. The current standard values for ergonomics were also taken into account when selecting the label roll size. For highest quality requirements, the system can be expanded with an integrated barcode reader/2D code reader.

Bluhm Systeme GmbH

www.bluhmsysteme.com