Predictive Maintenance as a focus at the Hannover Messe

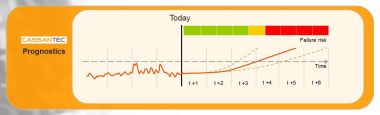

Repairing components only after a fault has occurred – that was yesterday. Today, sensor technology and IT enable predictive maintenance of production machines. Thanks to the linking and communication of machines, products and components in a digital network within the Industry 4.0 environment, operators of plants and machinery can continuously collect data on the condition of machine components, combine these data with information from external systems (such as ERP or CRM) and analyse the data to predict the optimum maintenance dates. With Predictive Maintenance, PM for short, impending failures are detected in good time, processes speeded up and production downtime avoided – that is the expectation.

That the hopes resting on PM are not unjustified is evidenced by a current study of the World Economic Forum and the consultancy Accenture: according to this study, savings in planned repairs amount to 12 %. Maintenance costs fall by almost 30 %. Unplanned downtime is reduced by 70 %.

In recognition of the growing importance of Predictive Maintenance, the forthcoming Hannover Messe will for the first time devote a special display section with an integrated collective stand to this theme.