Sacmi Heavy Clay supplies complete plant to Gres Aragón

The line will be used to make a vast range of products, spanning in size from 12 x 24 mm to a maximum width of 600 mm and maximum length of 1 800 mm (plane-ground, post-firing), including ventilated facades and large step elements. Installation and start-up are scheduled for this summer.

Designed for seamless integration into the existing plant, the line supplied by Sacmi Heavy Clay is exceptionally flexible, enabling high product quality and considerable energy savings. In this connection, the firing solutions are essential to that quality: Central element is the all-new IEM single-channel roller kiln, equipped with all the latest Sacmi technology to ensure maximum quality and lower consumption. The kiln is equipped with modulated air/gas combustion system control; it also features an advanced heat recovery system (MDR), used to heat the combustion air, while optimization of production and quality performance is ensured by control software that also handles any gaps in production. The order also includes the supply of a new universal forming system for both small and large sizes that offers high efficiency and output capacity.

The complete cutting and dry smoothing line requires no water, resulting in reduced environmental impact and lower disposal costs – a new development in extruded ceramics.

With Nuova Sima, a Group company, Sacmi has also integrated the entire production plant on the basis of roller box or platform storage systems. These are handled by latest-generation laser-guided LGV vehicles that link up the production islands.

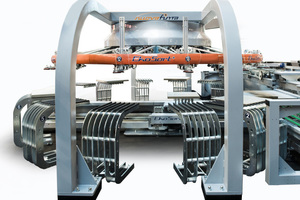

Sacmi is also supplying all end-of-line solutions. These include the cutting-edge automatic Flawmaster 5G vision system, developed by Surface Inspection. Other advanced solutions from Nuova Sima include equipment for forming stacks to be packaged (new Ekosort for large-size products) and the automatic Ekoroll 180 packager, which offers unique technology in terms of flexibility, efficiency and environmental-friendliness thanks to a revolutionary packaging system fed by rollers instead of the traditional die-cut carton magazine: the result is less waste and lower disposal costs, optimized consumption of raw materials such as cardboard and glue, plus guaranteed product quality on products with high unit value such as large slabs.

Sacmi Imola S.c.r.l.

www.sacmiheavyclay.com