Tracking down defects

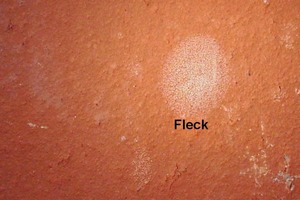

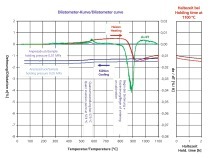

What to do when products or materials do not deliver what they promise? In wide-ranging enquiries, industry partners describe their problems and report “suddenly occurring curious product defects”. People are quick and only too willing to make raw materials or bodies responsible for defective product quality. Occasionally they are right, if you look, for example, at lime inclusions, gypsum-driven drying efflorescence or iron-mineral-related lumps. These can be tracked down with classical raw material analyses. But that is not always the case. Sometimes spalling occurs without any identifiable causes. Or marks appear, which, despite preventative use of additives, impair the look of the product. Sometimes it is also only a guess that can hardly be proven, but only confirmed later as a result of some random realization during operation. On the basis of several examples, the principle of the “reverse search” is presented. Here the use of high-tech analysis instruments and sometimes creative “try-outs” in small-scale laboratory tests are important tools in finding causes and eliminating problems.

Dipl.-Ing. Alexander Eppner,

IAB – Institut für Angewandte Bauforschung Weimar gGmbH