Utilization of blast furnace flue gas by-products in the manufacturing of clay bricks

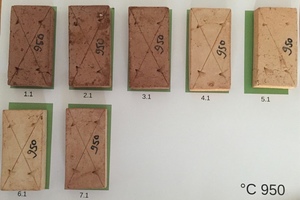

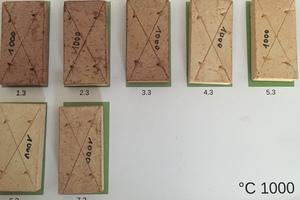

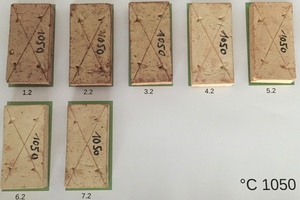

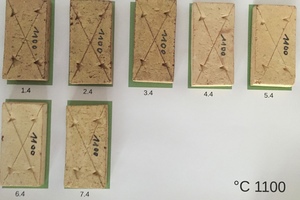

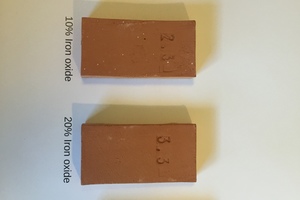

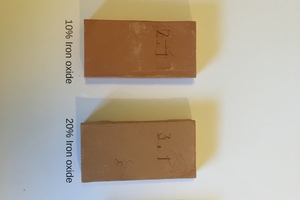

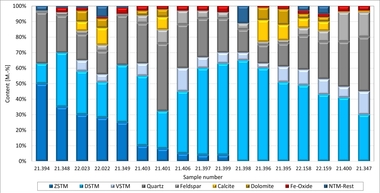

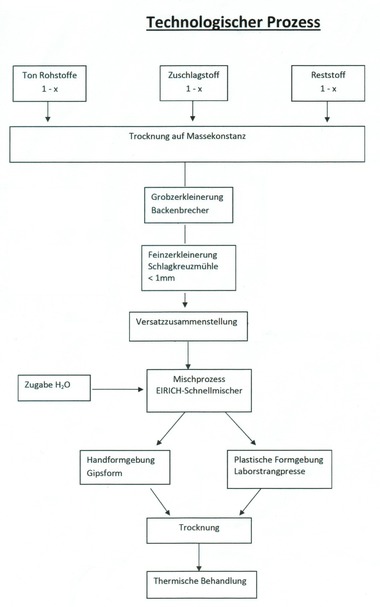

In the scope of a project, waste materials from steelworks in France, the USA and Italy were analysed and their suitability for utilization in brick plants assessed. Besides increasing the density, the additives influence the fired colour, mostly in the direction of red shades.

1 Introduction

The use of suitable waste materials that do not negatively impact heavy clay product characteristics and public product perception can certainly be considered valuable, environmentally friendly alternatives to traditional raw materials.

It is important that materials should not have any negative effects on the manufacturing cycle, or such effects should be offset by economic advantages. The waste materials should also be available in sufficient quantities.

Such by-products are produced, for example, in the steel making in blast furnaces and used in manufacturing ballast concrete...