Elster Kromschröder presents new Protective System Control FCU 500

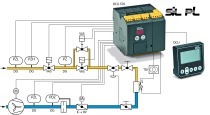

The new Protective System Control FCU 500 monitors various safety conditions such as minimum and maximum gas pressure and air pressure, and carries out a standard-compliant pre-purge. At the same time, an extended tightness test function monitors the main valves and carries out a system tightness test during system start. A special algorithm allows time-saving testing in the case of large test volumes. For increased operational safety, high-temperature monitoring can be performed in conjunction with Kromschröder burner control units using a twin thermocouple to be directly connected.

The functions combined in the FCU 500 can be precisely adapted to the requirements of the respective heating equipment using parameterization. The Protective System Control FCU 500 has been specially developed for installation in control cabinets and features tried-and-tested operation on the unit and an optical interface for programming and diagnostics using the PC software BCSoft. In addition, the FCU 500 can be directly controlled from the control cabinet door with the help of a separate operator control unit.

The new Internet-based system planning platform KST is available as planning support for the protective system as well as for the design of the entire heating equipment. KST offers many tools for the effective and safe implementation of heating equipment.

Hall A4, Stand 504