Saving energy in clay brick production by use of

vibrating cutting wires

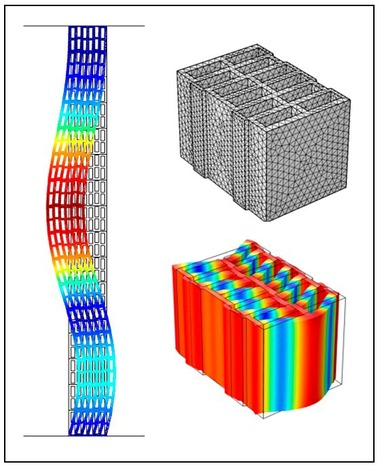

If vertically perforated clay bricks are to display the desired insulative properties, their bodies must be appropriately porous. This is usually achieved by adding combustible, void-forming additives derived from waste material from the papermaking, wood processing and packaging sectors. As the insulation requirements to be met by bricks become increasingly stringent, more and more porosification agents – in the form of papermaking sludge, sawdust or shredded polystyrene from old packaging material – have to be added to the clay. However, the fibrous structure of such additives can cause the cut face of the brick to deform. This problem can be minimized by adopting appropriate cutting technology. Otherwise, the fibres can cause the cut face to “smear” so badly, that some of the core holes are closed off. That, in turn, impedes both the flow of drying air through the hole and the expulsion of water vapour from the hole during the subsequent drying process.

Both defect sources can be reduced or even prevented, depending on the material characteristics. In most cases, this can even be achieved with less force applied to the cutting wire.

In the case of unporosified facing bricks, the problem is less to prevent deformation of the green bricks than to enable good cutting despite reduced batching water and with no change in applied force – or with the same amount of gauging water and less force applied to the cutting wire.

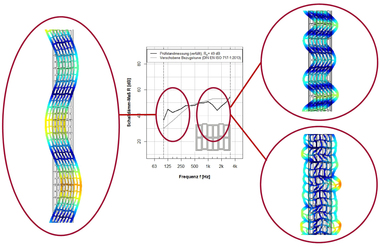

Trials performed in the course of an IZF research project yielded consistently positive results for the use of a vibrating cutting wire. Braided cutting wires, with their elevated inherent elasticity, were successfully employed as a means of preventing wire breakage cause by operation at resonant frequency. The experiments revealed that, for each increase in cutting speed, the frequency of vibration must be altered accordingly in order to preserve the positive “saw effect”.

To enable application of high-frequency vibrations, the wire should be moved by a piezoelectric drive mechanism of the kind commonly found in today‘s high-precision mechanical engineering applications.

Eckhard Rimpel, Brick and Tile Research Institute Regd, Essen, Germany