New Kiln Car Cleaning System made by Lingl

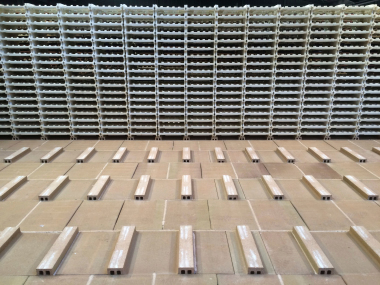

The usage of the Lingl kiln car cleaning system offers several advantages for the operation of brick plants: The life span of the refractory decks is increased due to regular cleaning of the kiln cars after every kiln passage. Sand and brick debris which would otherwise penetrate into the joints of the kiln cars are gently removed. The Lingl cleaning system is equipped with special lateral nozzles for thorough cleaning of the kiln car lateral sealing blocks, in order to increase the life span of the kiln labyrinth. By this fully automated system time and effort which are required for the manual maintenance of the kiln cars are reduced to a minimum.

For the designers of the Lingl kiln car cleaning system the most important aim was to make sure that this system will meet the same quality features as all other equipment and systems of Lingl. The cleaning system integrates into Lingl factories without any problems. This also applies with the compatibility of the well-established and user-friendly Lingl machine control system MBV on the basis of Siemens Simatic S7 hardware.

Of course, Lingl offers its cleaning system as a stand-alone solution as well. This enables potential customers to combine this system with existing car circulation systems of other suppliers.

The Lingl cleaning systems have been designed in order to adapt individually and in a simple manner to the most various car designs. The machine can also be combined with a removal device for refractory draught blocks.

The stand alone control system design complies with current EN standards. The control provides direct access to the machine functions via an operator touch screen panel and standard controls. The cleaning system carries CE markings for Europe as well as the UL certificate for the American market.

The system is delivered ready to use with a cyclone dust extraction filter unit for dust and particle separation. This includes a reverse jet system for controlled cleaning of the extraction unit filters.

The wholly-owned subsidiary Lingl UK Ltd. based in Congleton near Manchester, United Kingdom, was set up by Hans Lingl senior in 1964 and has been producing complete production plants for the heavy clay industry since that time for Lingl. In the course of the revision of the product portfolio of the Ling group some years ago, Lingl UK has now specialized in the development and manufacturing of Lingl transport systems for tunnel kiln cars such as transfer cars, rope haulages and pushers. The know-how of Lingl UK provides a solid basis for the design and production of the cleaning system. The worldwide servicing of the system is carried out by the reliable Lingl service team.