Investing in quality and environmental protection

Thanks to an additional surface inspection system by ibea, every roofing tile that leaves the plant first gets an optimal checking. Each individual tile is photographed and inspected for cracks, dimensional accuracy and perfect surface quality. Any deviation beyond close tolerances is recorded and the affected tile immediately rejected. The first inspection comes right after drying. Any tile not in conformance with the plant‘s high quality standard is physically rejected, hence saving both raw materials and energy. The system not only guarantees maximum product quality, but also makes it possible to very quickly analyse causes of defect and keep the production process optimized. Just under 4 000 roofing tiles per hour are produced.

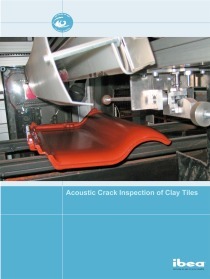

After firing, the tiles undergo their next surface inspection and dimensional check. This includes a hammer test in which the tile is tapped with a hammer and the resultant sound picked up by a microphone for frequency/sound-power analysis. The system detects even the most miniscule of defects in the roofing tiles. The hammer test is based on a comparison of the thusly produced sound with the pure ring of a large number of reference tiles selected from Röben‘s production output in Brüggen.

The just-completed investment programme at the Röben roofing tile plant in Brüggen also encompassed an engobing system designed to ensure uniform, resource-conserving application of glazes and engobes.

Last but not least, the old heat-shrink wrapping setup was replaced with a modern new hood-stretching system – again saving both energy and film.

The plant is presently working at full capacity, i.e., turning out 20 million roofing tiles per annum.