Ceratec successfully commissioned new Cutters and an Innovative Tunnel Drying Concept

Ceratec, a leader in engineering solutions, has achieved a groundbreaking feat with the successful development and commissioning of a unique tunnel dryer concept at the Ibstock Aldridge factory. This pioneering project offers enhanced efficiency, reduced energy consumption, and alignment with Ibstock‘s Environmental, Social, and Governance (ESG) Strategy.

Ibstock UK – Aldridge factory

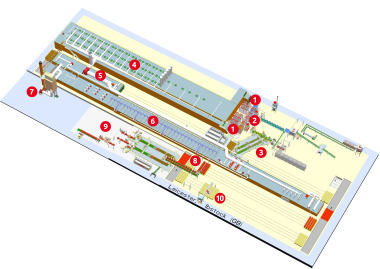

The Ibstock Aldridge factory is a production facility for extruded bricks and can run continuously seven days a week, with 11 hours of effective production time per day. Bricks undergo a series of processes, including extrusion, texturing, sanding, and cutting into slugs before being cut into either BS65 or BS73 bricks. The facility produces 28 Million bricks/year.

Energy Efficiency

The tunnel dryer, a central component of the production line, functions as a classic tunnel dryer during operational hours. But unlike traditional dryers, which remain idle during non-production periods, Ceratec‘s innovation maintains the relative dryer curve outside production hours by moving the dryer front. This is made possible through the development of specialized control software, allowing for efficient management of the drying process without the need for continuous loading and operation of the dryer.

Compact design

Ceratec‘s tunnel dryer concept not only revolutionizes operational strategies but also addresses space and energy concerns. By incorporating a compact design, the dryer fits seamlessly into a new, smaller building footprint. This optimization not only maximizes available space within the factory but also significantly reduces energy consumption compared to the former chamber dryers.

The integration of this innovative technology underscores Ceratec‘s commitment to sustainability and aligns with Ibstock‘s ESG objectives.