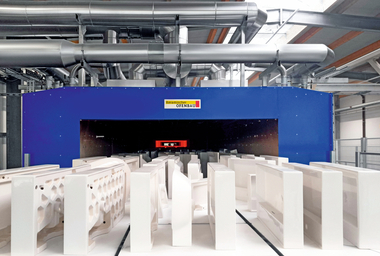

Keramischer OFENBAU GmbH: Your global partner for thermal solutions

Continuous and discontinuous kilns for your efficient production: Your reliable partner for sintering in the ceramics industry. Keramischer OFENBAU’s engineering of technologically advanced kiln plants is based on more than a century of kiln engineering tradition. With the optimal mixture of competence, efficiency, and innovation, the kiln manufacturer has successfully exported state-of-the-art kiln plants to more than 50 countries worldwide.

An experienced and flexible team and well-organized structure contribute significantly to one central goal: Building the kiln of the future in an interplay of profound expertise, precise but flexible engineering, and decades of experience. The Keramischer OFENBAU team designs cutting-edge technology for new kilns and modernises existing kilns in efficiency, safety, and quality. These economically and ecologically sensible optimisations allow for energy and emission savings of up to 50 % with additional potential thanks to Keramischer OFENBAU heat exchangers.

Tunnel, shuttle, and roller kilns heated with gas, electricity, or hydrogen – all for your optimal production. Thanks to electric heating, new plants can achieve the goal of energy independence by producing their own energy. Existing gas-fired systems can also be prepared for operation with up to 100 % hydrogen with EnerViT H2 ready.

Keramischer OFENBAU implements sophisticated technological concepts with optimised setting technologies for highly automated systems with an excellent temperature distribution for the highest quality ceramic production. Additionally, processes are optimised with modern energy management systems including weighing technology. Tunnel kilns can impress with a high setting width and shuttle kilns with a high proportion of first quality final products.

Technical and structural ceramics, table- and sanitaryware, fuel cells and solid-state batteries – Keramischer OFENBAU provides you with the optimal temperature distribution and maximum efficiency for your perfect production quality. Your reliable partner for maximum quality offers tailor-made solutions and sustainable optimisations catering any specific need.

Energy efficiency begins with the right mindset: Keramischer OFENBAU provides cool ideas. For hot topics and economical kiln plants.

For more information on the kiln of the future, get in touch and meet Keramischer OFENBAU experts at ceramitec 2024, booth A5.322!