Non-destructive measurement of refractory lining thickness

StratoTest 4500C from ElektroPhysik significantly facilitates lining thickness measurement in industrial kilns in the brick and tile industry

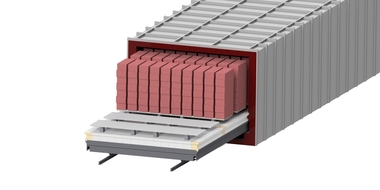

With the StratoTest 4500C lining thickness gauge from ElektroPhysik, the residual stone thickness of refractory linings in industrial kilns in the brick industry can be determined extremely quickly and precisely. The non-destructive, electromagnetic measuring method allows very high time and cost savings for the operators of corresponding kilns. Kiln downtimes are significantly reduced by reducing the number of boreholes from up to 200 to just one.

With the StratoTest 4500C, the lining thicknesses of cement, dolomite, magnesite or fireclay bricks in industrial kilns can be determined very quickly and without great effort. For this purpose, a plate-shaped eddy current probe with a diameter of 33 centimetres is used in the StratoTest. When the measuring probe approaches the metallic furnace shell, which serves as a measuring reflector, the electrical probe values change depending on the distance. The electromagnetic measuring method then displays exactly the mean value of all thickness values in the probe‘s area of influence. At the same time, the battery-operated measuring device is extremely user-friendly. The handle of the 1,860 g probe can be extended to a length of up to 145 centimetres and is thus individually adjustable.

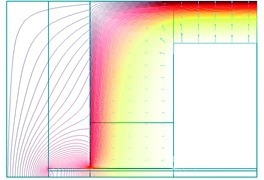

Electromagnetic measuring method

To carry out the measurement, a test hole is first drilled in the furnace section to be examined. On the one hand, this serves to assess the structure and condition of the stones and masonry, and on the other hand, the height of the stones up to the steel casing can be determined by means of the borehole. The measuring probe of the StratoTest 4500C is then placed at the drilling point and adjusted to the existing stone thickness by means of the individual calibration option of the device. The entire lining can then be measured. The electromagnetic measuring method of the StratoTest guarantees fast and user-friendly measurement with high accuracy of up to 3 percent of the measured value.

Exact documentation and reproducibility

The evaluation unit of the StratoTest 4500C can be connected to a PC or laptop via cable or wirelessly via Bluetooth. The measured data can be read out as a CSV file and used and processed directly for documentation purposes.