150 years of tradition and innovation –

The new development laboratory at Prince Minerals

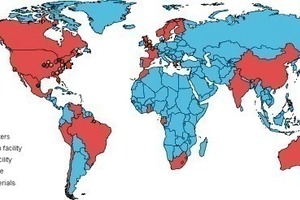

The company Prince Minerals, one of the leading manufacturers and merchandizers of naturally occurring minerals and pigments for a vast range of applications, was able to celebrate its 150th anniversary in 2008. Today the company operates six production sites in the USA, which also supply the markets in Canada, Mexico and South America. Prince Minerals Limited in the United Kingdom, with two production sites, is responsible for the European market. The main customers for the mineral additives are the brick, refractory, glass, ceramic, foundry, cement and steel industries.

1 Introduction

Established in 1858, Prince Minerals Inc. developed from a supplier of red iron oxide pigments for paints and coatings to a leading supplier of processed natural minerals.

In 2007 Prince started the construction of a production site and development laboratory with a total hall space of around 40 000 sq.ft. (approx. 3 716 m²) in Monroe, NC, USA. The laboratory with about 3 000 sq.ft. (around 279 m²) of laboratory and office space, began work at the end of 2007. Production in Monroe commenced in spring 2008.

2 The new central laboratory in Monroe

Monroe – the site for the new...