Industrial dryer technology: optimized air circulation

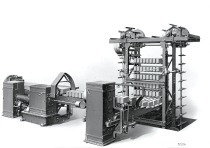

In the face of rising energy prices, brick producer Heluz relies on dryer pallets with an energy-efficient profile. Like the tunnel dryer, these have been supplied by the plant and machine engineering company Keller HCW. The manufacturing know-how came from the sheet metal specialist Graepel, whose engineers also accompanied the development.

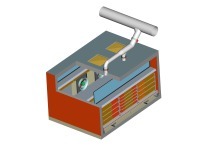

On the 2 200-mm-long and 500-mm-wide pallets, the freshly pressed bricks travel through the dryer. During the 16-hour drying process, the bricks and pallets are exposed to temperatures up to 170° C. The special features of the new pallets are their high structural strength, their low dead weight and the excellent air circulation. For the latter, the important factor is their open cross-section, i.e. the ratio of the air perforations to the area of the substrate material: the better the air distribution is, the shorter is the expensive drying time.

The development partner Graepel is a leader in its field: premium manufacturers such as Mercedes-Benz and Caterpillar rely on its ventilation sheets designed to fulfil a similar purpose. The pallet for Heluz is designed for a load of 680 kg, the deflection being a maximum of 5 mm in the lengthways direction or 2 mm crossways. An empty pallet weighs less than 100 kg and consists of moulded, welded and hot-dip galvanized sheet plates.

The results have been convincing: 3 300 pallets have been ordered.