Innovative kiln systems at ceramitec 2009

At ceramitec the manu facturers of industrial kiln systems will be presenting creative solutions for process-optimized, energy-efficient firing, covering the different requirements of the different fields of ceramics.

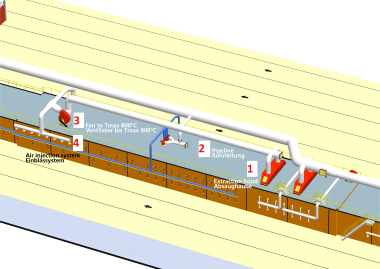

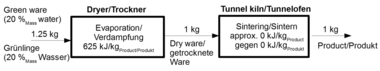

The new and improved kiln and firing concepts on display will include, for example, the 3-channel roller kiln and the new high-temperature vacuum lock from Eisenmann for complex sintering processes in continuous kiln systems at temperatures of up to 1 700°C. Not new, but taken up by many plant manufacturers, is the use of heat recovery systems. This enables a certain quantity of energy to be used twice, i.e. returned to the process or utilized in other processes. Energy savings here can be as much as 25 per cent.

The use of new-style burners and intelligent measurement, control and regulation systems promises precise, highly flexible firing processes and the highest level of energy efficiency. Sacmi, for example, has developed a firing process for tiles in which through regulation of flame length and intensity even temperatures can be achieved in the tunnel kiln and the atmosphere changed from oxidizing to reducing. CTB ceramic technologie berlin combines newly developed ‘True Blue’ burner with its measurement, control and regulation systems. The critical factor in complex firing processes is the precision and speed with which the controls operate.

Not just in this segment is ceramitec 2009 offering a broad range of products and innovations, it is also a great place for visitors to find out how to significantly improve flexibility, process accuracy and energy consumption including on existing plant, through the use of modern firing, measurement and control systems, ‘light’ kiln furniture and by eliminating energy eaters on kilns and kiln cars.

More details available on www.zi-online.info.