Simulation of the firing of ceramic ware

Part 1: Understanding the firing process in tunnel kilns

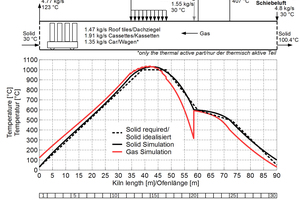

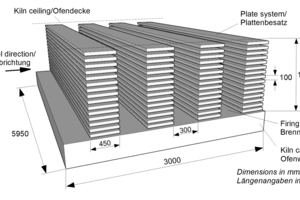

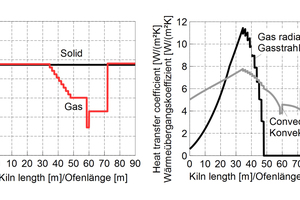

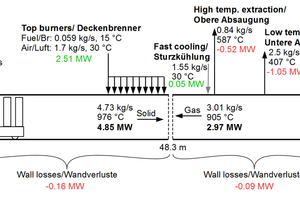

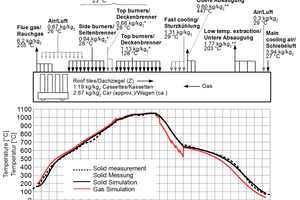

In this paper, the firing of ceramic ware in tunnel kilns is analysed with the help of a mathematical process model. As an example, the firing of horizontally stacked roof tiles is simulated. In addition to the energy balance, the influence of design, operating and setting parameters on the firing curve is shown. Based on these results, concepts for the further development of the tunnel kiln process are presented in a second part entitled “Simulation of the firing of ceramic ware – Part 2: Roadmap for CO2-free production by 2050”.

1 Introduction

The production of building ceramics such as clay pavers, facing and hollow bricks and roof tiles is an energy-intensive process. Drying and firing in industrial practice require on average about 2 300 kJ per kg of fired ware [1]. This energy is usually supplied to the process in the form of natural gas. In relation to this, the evaporation of the initial water content (mixing water) determines the theoretical minimum energy demand (»1).

If the average water content is assumed to be 20 % by mass, the minimum energy demand for drying is 625 kJ per kg of fired ware. The sintering...

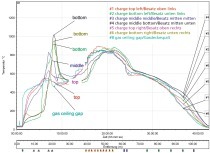

![»3 Required firing curve for roof tiles according to [13, 14]](https://www.zi-online.info/imgs/1/5/3/0/6/3/8/tok_f565627ad0e7fbda8c4fae02bfbd6a91/w300_h200_x600_y318_Redemann_3-1acfcf9e98acb7fe.jpeg)