Lingl Converts a Roof Tile Plant into a Plant for Accessory Roof Tiles for Koramic

At Lantenne, approx. 18 km to the west of Besançon, Koramic Dachprodukte GmbH & Co. KG, a subsidiary of the Austrian Wienerberger Group, operated a roof tile plant which was to be converted into a plant for the sole production of accessory roof tiles. Lingl was entrusted with the reconstruction of the plant and the delivery of the technical equipment with the objective that any handling system has to be designed for an enormous product variety.

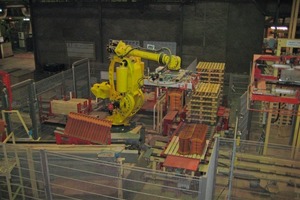

Lingl integrated the existing chamber dryer into the new concept which in the future will be automatically charged and discharged by a new combination of finger car and transfer car. A camera-guided robot puts the dried roof tiles into the H-cassettes - free of impacts and absolutely gently – and without any manual work. All in all, on three setting and unloading tracks kiln cars with different types of H-cassettes are positioned for the respective accessory roof tiles, serving also as a buffer for the reloading of kiln cars and cassettes. The fully automatic operation allows for an integrated car tracking.

The technological characteristics of the two existing tunnel kilns were adapted to the requirements. The kilns are controlled by a new process computer. The production management enters the data via WinCC operator interface.

Lingl also adapted the packaging installation to the special features connected with the production variety at Lantenne. Like all other components in the plant the packaging installation is reacting in a very rapid and flexible way to any change of the products.

After start of the reconstruction by mid of 2006 the converted and modernized plant was set into operation in 2008 as scheduled. Since this time the plant is being operated in three shifts around the clock.

With the conversion of the plant from U-cassette to H-cassette technology into a modern plant for accessory roof tiles Lingl again gave proof of its capability with regard to the development and realization of individual solutions.