Lingl supplies one of the the world‘s largest tunnel kiln for H-cassettes

Today Tondach Gleinstätten AG is the market leader in the production of roof tiles in Central and Eastern Europe. Already in 1992 the company successfully started expanding into Eastern Europe and is still pursuing this strategy. In Hungary alone the company is holding eight factories in six locations. From 1992 to 2009 the total amount invested there by Tondach Ungarn largely exceeded 150 million €. Currently about 400 employees are involved in the production of extruded roof tiles as well as large and small-sized pressed interlocking roof tiles, accessory elements and wall bricks. The sale of the high-quality products is organized by Tondach primarily on a business-to-business basis by means of the company’s own sales force. The actual “highlight” in the range of production facilities of Tondach Gleinstätten AG was erected at Csabai near Békéscsaba in the eastern part of Hungary. The new factory “Csabai II” has an annual production capacity of approx. 30 million large-size pressed interlocking roof tiles and approx.

2.5 million accessory elements. Named “Rumba, Bolero and Twist” the largest roof tiles of the Tondach Group with a calculated measurement of 9.3 pcs/m² are produced there.

For this gigantic project Tondach themselves acted as the general contractor and included various equipment manufacturers in the realization of the project. Lingl was ordered to supply a tunnel kiln for H-cassettes with the appropriate preheaters. The location had not been unknown to Lingl as the first plant in Hungary “Csabai I” had already been modernized by Lingl in various stages.

With a length of more than 236 m, a channel width of 9.30 m and a channel height of 1.90 m the Lingl tunnel kiln for H-cassettes is one of the largest tunnel kilns known throughout the world. The kiln car charge is 18 cassette layers high in 6 rows so that the total charge of a tunnel kiln car is 2592 roof tiles! Beside various circulation systems for air homogenization the range of equipment of the high-quality tunnel kiln made in brickwork also involves the gas firing installation, a rapid cooling system, extraction systems above and below the quartz inversion, an air injection unit and an air supply unit. Kiln entrance and exit are furnished with vestibules for taking up one kiln car each. Of course, the Lingl tunnel kiln is also equipped with a controlled undercar cooling system which serves for constant pressure conditions in the combustion zone of the kiln.

An interesting solution was found for the preheaters: they are charged with

3 cars of accessory elements and 5 cars of roof tiles and preheat the roof tiles and the accessory elements at 200° C in two separate systems.

The tunnel kiln is equipped with 36 burner groups: In the main firing zone it is top-fired with natural gas. For such a wide firing channel this type of firing system is the only reasonable one to ensure a good temperature homogenization combined with a low energy influx. Due to the kiln width the high-velocity gas burners in the heating-up zone are also installed in the roof in order to feed additional energy and to achieve a homogeneous temperature distribution by a high flow speed. For utilizing the fuel as efficiently as possible the complete firing installation is equipped and insulated appropriately for the use of pre-heated combustion air. The combustion air temperature there is up to 300° C. Subject to a maturing temperature of 1060° C the kiln passage time is

23 hours.

At a first glance the firing installation seems to be rather amply dimensioned. Its design was based on large-scale Lingl laboratory investigations and the special demand of Tondach for high-quality firing results with first-class quality features of the roof tiles.

Due to the large quantity of auxiliary firing means an H-cassette tunnel kiln produces a relatively low amount of excessive exhaust air available for further disposal. Also in the kiln at Csabai II the available volume flows are fed to the preheaters and the tunnel dryer via a combined pipe system for an optimal energy utilization.

Another novelty in the Csabai II plant was to equip the flue gas chimney of the kiln with an flue gas cleaning system in order to comply with the air pollution control regulations applicable in Hungary.

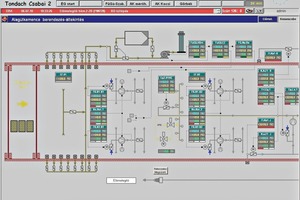

The kiln is controlled by the Lingl process control system on the basis of the software package WinCC and the Siemens S7 automation technology. The Lingl control system allows the process-dependent control and regulation of the tunnel kiln in a very user-friendly manner. Only the generation of firing curves for new products at the computer monitor requires the intervention of professionals – all other process parameters are preset automatically by the control system. The integrated and continuously operating process data archiving system with reporting function facilitates a professional analysis of the firing process. In this way the Lingl control system supports the constant optimization and improvement of the achieved quality and energy values. The positive experiences with the Lingl process control system induced the customer Tondach Gleinstätten AG to decide for the installation of another Lingl control system for the dryer of another sub-contractor in the Csabai II project.

Tondach Gleinstätten AG has got an excellently trained and practice-experienced staff. Therefore the co-operation between Tondach and Lingl made it possible to commission the kiln and reach full capacity very quickly. The achieved results with regard to product quality, waste and energy consumption did not only meet the target values but exceeded them significantly. The chairman of Tondach Gleinstätten AG, Gewerke Direktor KR Franz Olbrich is satisfied: “I‘ have got close links to Lingl for decades, and also for this project my expectations were fulfilled at best – simply speaking: I can rely on Lingl.”