New Extruder Type 750 ER for a larger de-airing chamber

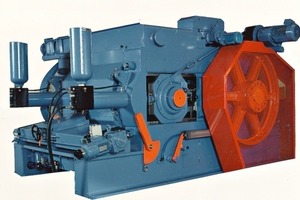

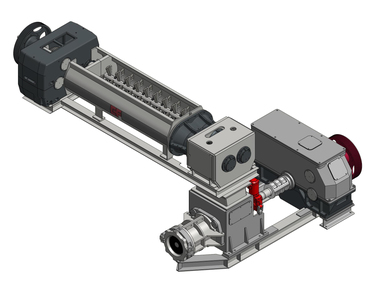

The mixer, which together with the extruder forms the extrusion unit, has also been reworked: the diameter of its outlet auger has been increased to 550 mm in order to match the clay feed flow to the extruder‘s maximum capacity of 100 t/h.

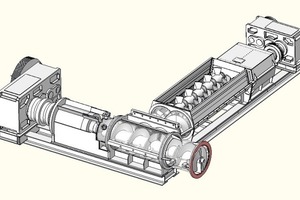

The extruder boasts a de-airing chamber with a 40-% larger volume than that of the former model, the Type 650 ER. This significant increase in volume enables a 37-%-longer residence time of the clay body in the de-airing chamber, improving its de-airing, which is a key criterion in the homogenization of the clay body as this ensures the final quality of the products. The number of hobbles has also been increased to ensure better clay compaction at the auger exit.

This new extruder is based on the same design as that of the proven Pelerin extruders. It allows direct introduction of the clay under pressure into the inlet tank. This feature ensures adaptability for all types of clay.

Its structure has been designed so that the extruder unit rests on an even surface, all on the same height: this facilitates design of the concrete foundation supporting the unit, making it less expensive to build.

Outstanding accessibility, with ergonomic access at chest height, is a trump feature for customers: it saves time and shortens production downtime needed for maintenance. Easy accessibility was a key development criterion, reflected in the addition of direct access doors to the augers in the tank bottom and inspection windows for a view into the deairing chamber.

The new Type 750 ER Pelerin extruder profits from the experience and expertise intrinsic in the Pelerin trademark, with its acknowledged superior performance.