Verdés installs A-750-F filter mixer and a Magna 675 extruder in Belgium

The purpose of the investment was to incorporate new equipment capable of surpassing the production rates and working pressures achieved with the existing machinery, which was already working at the limit of its capacity. Verdés accepted this challenge, relying on its many years of experience in moulding and its new design of the Magna extruder, launched on the market in 2013 and equipped with the latest extrusion technologies.

A-750-F filter mixer

The model A-750-F is the largest machine in its range. It consists of a 1 800-mm-long open trough mixer that incorporates a compression zone of 875 mm where the clay is compacted against a grid, thus obtaining high efficiency in homogenization and removing impurities from the material in the process. The capacity of this model exceeds the actual production requirements at Dumoulin Bricks, allowing for future increases in productivity.

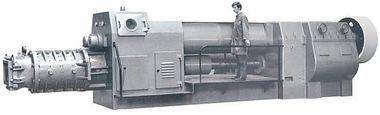

Magna 675 Extruder

The Magna 675 extruder has a production capacity up to 85 t/h, considerably higher than the previous unit.

With an auger diameter in the vacuum chamber of 675 mm and 650 mm in the front, it enables a pressure range up to 25 bar, which permits flexible production of different clay block formats. The higher applied pressure enables extrusion of drier or stiffer bodies, which reduces energy consumption in the downstream drying process.

After several months in production, the results are clearly visible: the working pressure has increased, giving more stability to the wet blocks and enhancing the productivity of some critical product formats. The two machines are currently working well under their maximum capacities, resulting in a reduction in the wear of the critical parts. The efficiency of the moulding process has been improved and Dumoulin Bricks is prepared for a future increase in production capacity.

Verdés S.A.

www.verdes.com