Thanks to the individual sorting system for pressed roof tiles, not even one cracked, misshapen or wrong colour roof tile will be delivered to the customers of Cerâmica Sotelha. The main aim of this new system installed by Equipceramic is to obtain a palletization system with a 100% rate of acceptable roof tiles and 0% customer complaints.

1 Technology

To achieve this aim, 3 600 roof tiles per hour are sorted one by one by means of a computer vision system or manually in a high-tech installation.

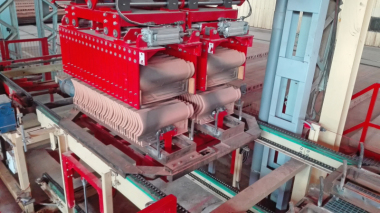

Kiln cars loaded with fired roof tiles, in packs of 28 units tied with refractory wire, arrive at the palletization station. These packs are supplied to the new installation by a computer-controlled gripper in order to go through an automatic process consisting of the steps below:

› �Automatic cutting and removal of wire

› �Individual setting of the roof tiles on two conveyors where they are sorted based on sight and sound by two workers (the workers can detect defective roof tiles based on the sound produced by the striking of an automatic hammer)

› �Having passed quality control, the roof tiles are set in packs with the possibility of height variation (4, 5, 6 or 7 roof tiles). This will enable Sotelha to deliver small packs to its customers, facilitating on-site handling

› �Bundling adapted to pallet format (between 900 and 1 200 mm)

› �Automatic strapping of these packs and distribution to the collection area by the robot

› �A robot waterproofs the roof tiles by dipping them into a mixture of water and waterproofing liquid, and palletizes them automatically

› �Pallet film wrapping

Flexibility

The current market is difficult and demanding. Offering a high-quality product to customers is not enough. In order to be more competitive it is necessary to offer an added-value product. This flexible and customer-specific solution implemented by Equipceramic enables roof tile manufacturers to supply a high-quality roof tile in user-friendly packaging adapted to customer requirements:

› �Possibility of manufacturing Portuguese and Marseilles-type roof tiles

› �Three different types of palletization (three different pallet sizes): one for the local market, another one for export, and one special format for roof tiles set upright

› �Several possibilities for palletization: Roof tiles in upright or flat position, and pallets with variable layers (3, 4 or 5)

› �Different roof tiles pack-making to facilitate on-site handling (4, 5, 6 or 7 strapped roof tiles)

› �Possibility of waterproofing or not, variation of the dipping cycle

› �Possibility of adding wood slats between pallet layers

› �Possibility of adding a cardboard sheet between layers of upright roof tiles.

Waterproofing

Clay roof tiles absorb a certain amount of water depending on their porosity. Water penetration into the tile can cause different types of damage, such as cracking due to expansion and later contraction, scum, frost damage, seams of dirt, growth of moss and mould, decrease in thermal insulation. Roof tiles can be waterproofed as a preventive measure to protect them from rain and its harmful effects. Waterproofing is a colourless treatment, which does not create a membrane, but prevents the capillary absorption of water without blocking the pores. Therefore it doesn’t alter the gas permeability of the roof tiles. At Sotelha, the roof tiles are dipped into a mix of water and waterproofing solution for a few seconds, and then they can be palletized.

But it is not always necessary to apply a waterproof treatment to roof tiles since the harmful effects previously mentioned also depend on the weather of the geographical area in which the roof tiles are to be used. In areas with rainy weather and wide temperature fluctuations, the roof tiles should be waterproofed. In other areas where temperature fluctuations are lower, waterproofing is not necessary. Since waterproofing process increases the product cost, it is very important to make the production line flexible in order to enable simultaneous manufacture of roof tiles with and without waterproofing.

This new dehacking, waterproofing and bundling line will provide the Sotelha plant with great flexibility, and at the same time it will ensure the manufacture of high-quality products. Furthermore, this new line will position Sotelha as a leading clay roof tile manufacturer, equipped with state-of-the-art technology, on the market.

Marc Carbonell

Project Manager Industrial Engineer